Factory making High Permeability Material - Fe-Based 1K101 Amorphous Ribbon – Malio

Factory making High Permeability Material - Fe-Based 1K101 Amorphous Ribbon – Malio Detail:

Description

| Product Name | Fe-Based 1K101 Amorphous Ribbon |

| P/N | MLAR-2131 |

| Width | 5-80mm |

| Thickness | 25-35μm |

| Saturation magnetic induction | 1.56 Bs (T) |

| Coercivity | 2.4 Hc (A/m) |

| Resistivity | 1.30 (μΩ·m ) |

| Magnetostriction coefficient | 27 λs (ppm) |

| Curie temperature | 410 Tc (℃) |

| Crystallization temperature | 535 Tx (℃) |

| Density | 7.18 ρ (g/cm3) |

| Hardness | 960 Hv (kg/mm2) |

| Thermal expansion coefficient | 7.6 (ppm/℃) |

Application

● Mid-frequency power transformer core, distribution transformer core

● Toroidal uncut cores for smooth filtered output inductors and differential mode input inductors for switching power supplies

● Noise suppression in car stereos, toroidal uncut cores for car navigation system chokes

● Ring-cut cores for PFC power factor correction in air conditioning and plasma TVs

● High frequency rectangular cut cores for output inductors and transformers for switching power supplies, uninterruptible power supplies, etc.

● Toroidal, uncut cores for IGBTs, MOSFETs and GTOs pulse transformers

● High power density variable speed motors, stators and rotors for generators

Features

● Highest saturation magnetic induction among amorphous alloys-reduce components size

● Low coercivity- Improve components efficiency

● Variable Magnetic flux rate – By different core heat treatment processes to meet the requirements of different applications

● Good temperature stability- Can work at -55°C -130°C for long periods of time

● Cores used in transformers are 75% more energy efficient than S9 silicon steel cores in terms of no-load losses and 25% more energy °C efficient in terms of load losses

● Short strip production process and low production cost (see Fig. 1.1)

● The strip has a special microstructure which determines its excellent magnetic properties (Fig. 1.2) and performance stability.

● The composition and process parameters of the strip can be quickly adjusted to meet different usage requirements.

● For new energy solar grid-connected inverters

Figure 1.1 Amorphous ribbon production process

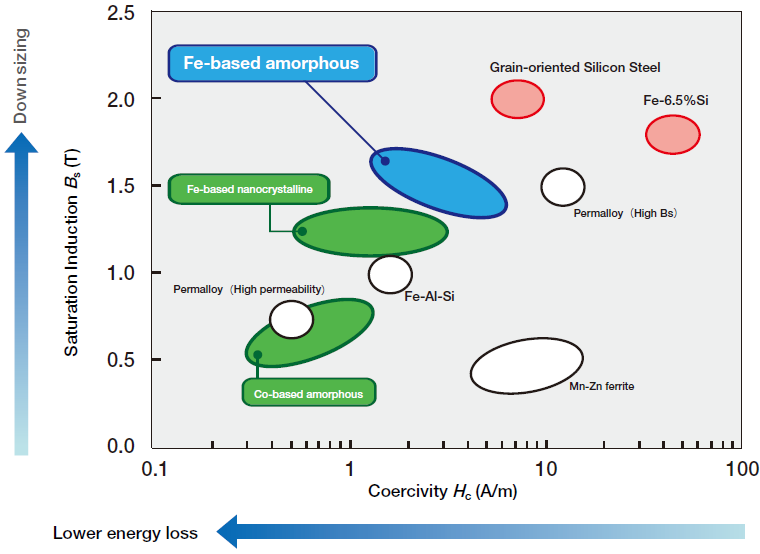

Figure 1.2 Bs versus Hc of different soft magnetic materials

Material comparison

| Performance Comparison of Fe-based amorphous alloys with cold-rolled silicon steel | ||

|

Basic parameters |

Fe-based amorphous alloys |

Cold-rolled silicon steel(0.2mm) |

| Saturation magnetic induction Bs (T) |

1.56 |

2.03 |

| Coercivity Hc (A/m) | 2.4 | 25 |

| Core losses(P400HZ/1.0T)(W/kg) | 2 | 7.5 |

| Core losses(P1000HZ/1.0T)(W/kg) | 5 | 25 |

| Core losses(P5000HZ/0.6T)(W/kg) | 20 | >150 |

| Core losses(P10000HZ/0.3T)(W/kg) | 20 | >100 |

| Maximum magnetic permeability (μm) | 45X104 | 4X104 |

| Resistivity (mW-cm) | 130 | 47 |

| Curie temperature(℃) | 400 | 740 |

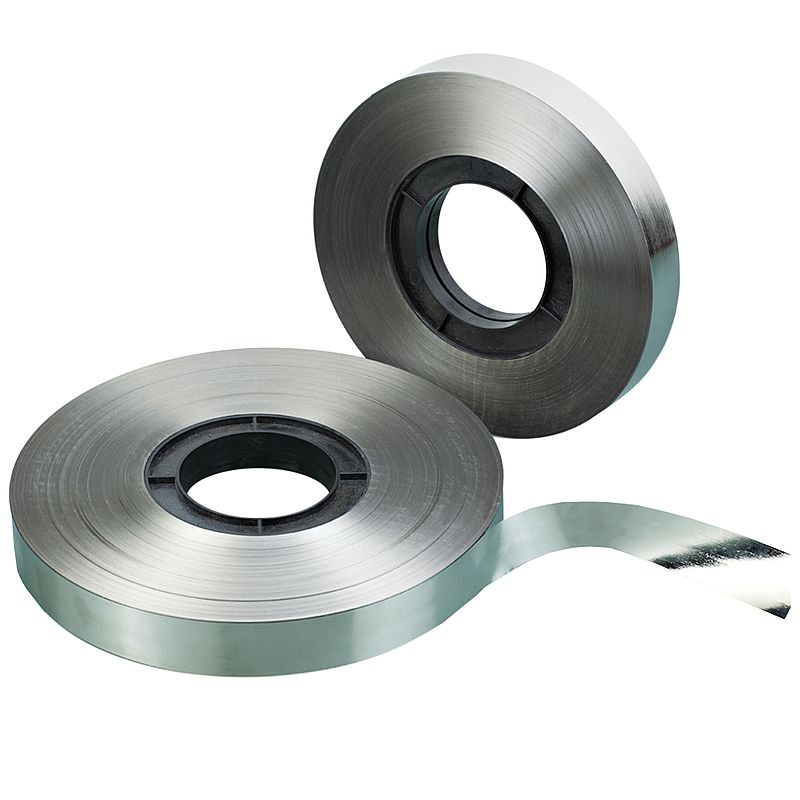

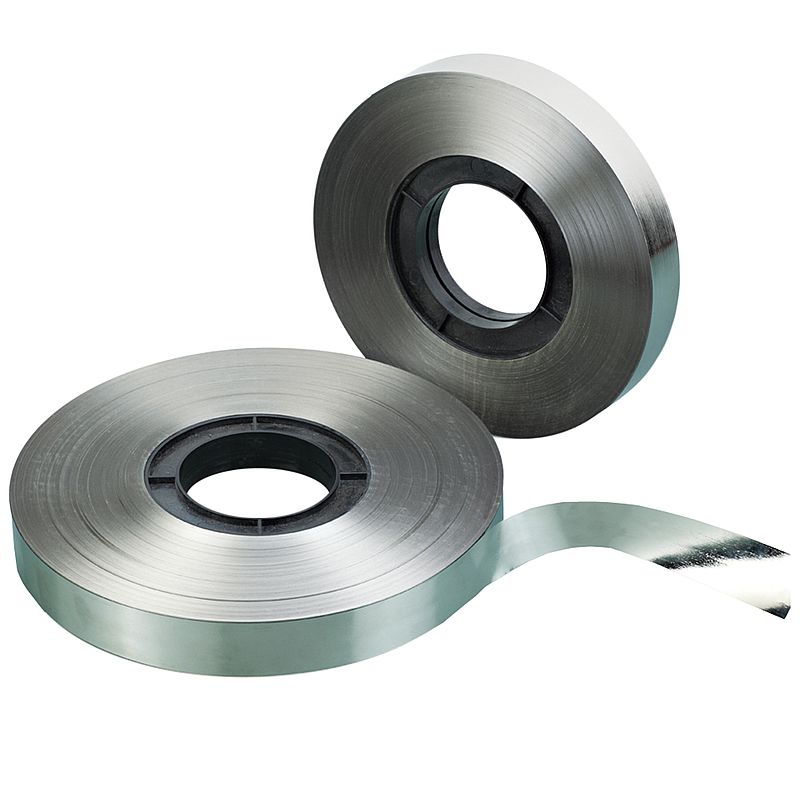

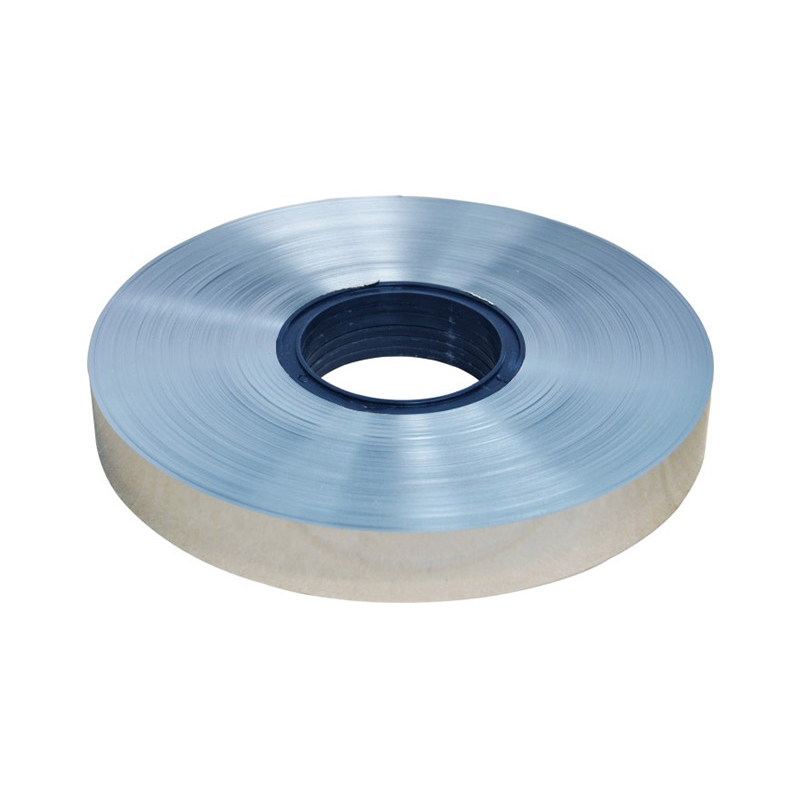

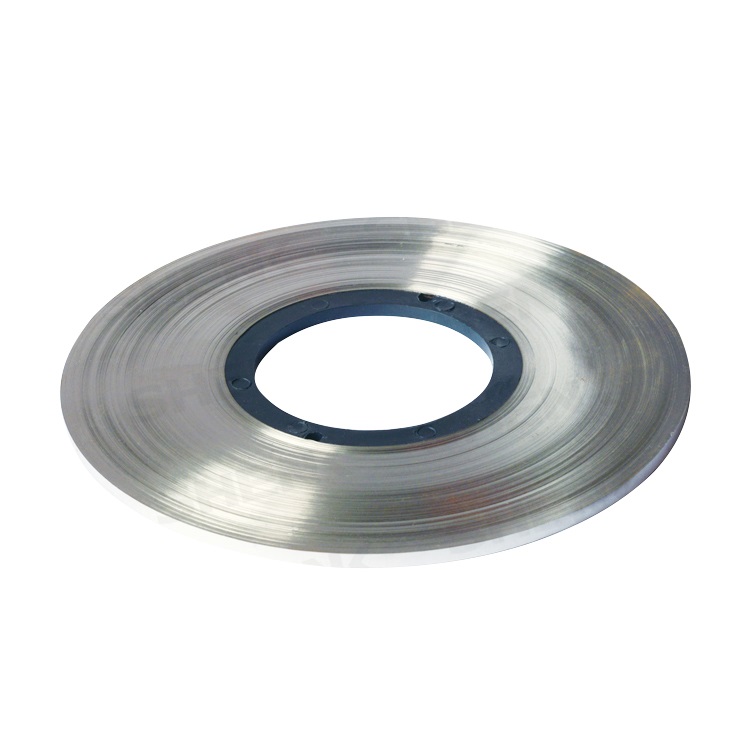

Product detail pictures:

Related Product Guide:

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for Factory making High Permeability Material - Fe-Based 1K101 Amorphous Ribbon – Malio , The product will supply to all over the world, such as: Anguilla, Australia, Birmingham, We've been always creating new technology to streamline the production, and give products with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to present our best service to satisfy all your needs! Remember to contact us right away!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!