Hot Selling for Tft - Fe-Based 1K101 Amorphous Ribbon – Malio

Hot Selling for Tft - Fe-Based 1K101 Amorphous Ribbon – Malio Detail:

Description

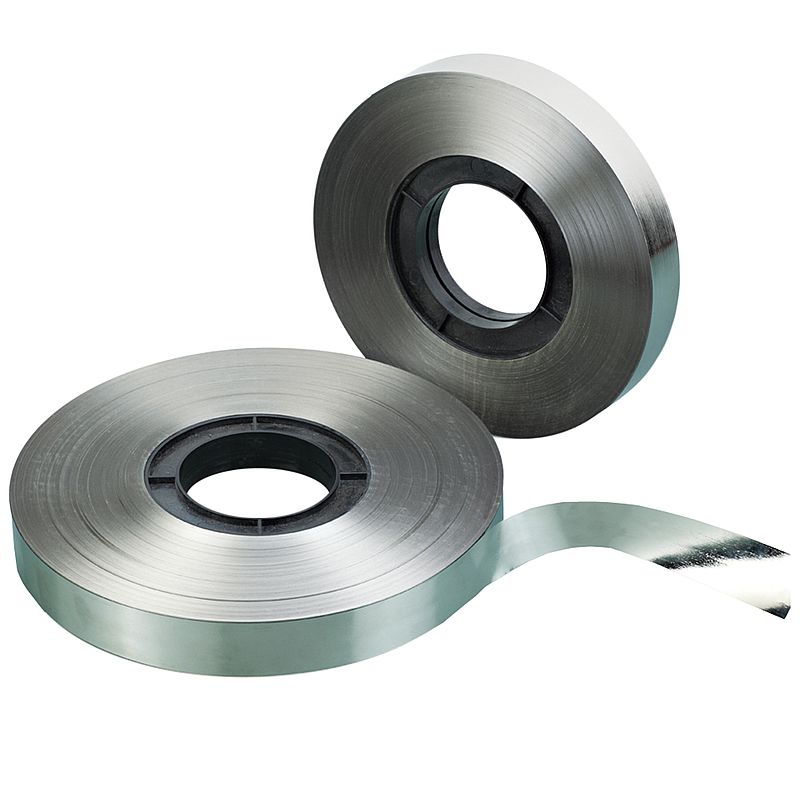

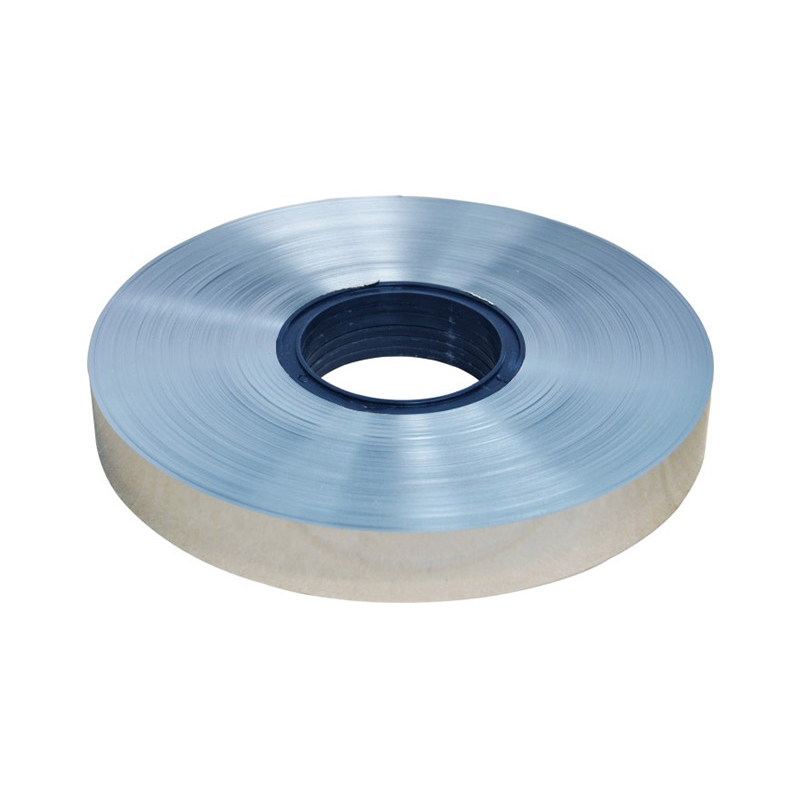

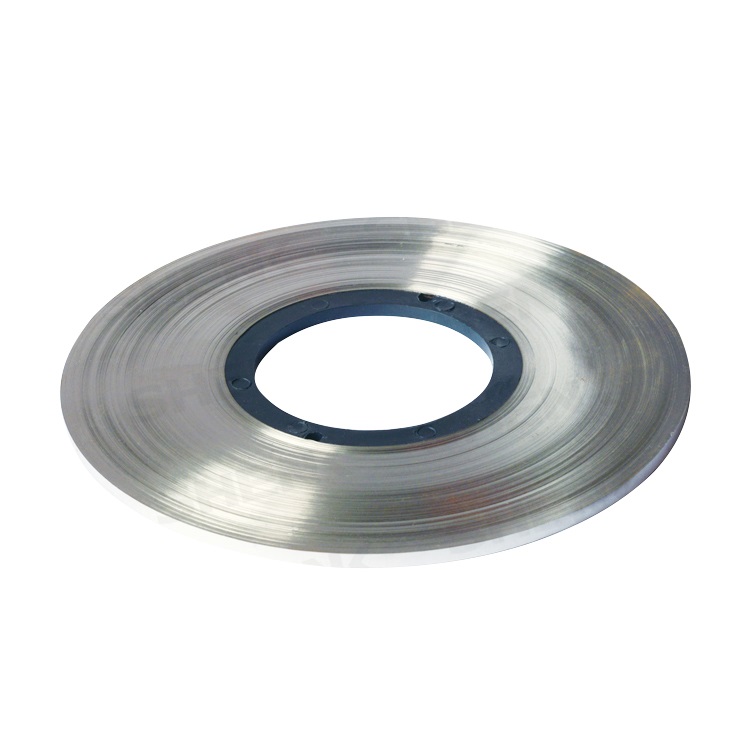

| Product Name | Fe-Based 1K101 Amorphous Ribbon |

| P/N | MLAR-2131 |

| Width | 5-80mm |

| Thickness | 25-35μm |

| Saturation magnetic induction | 1.56 Bs (T) |

| Coercivity | 2.4 Hc (A/m) |

| Resistivity | 1.30 (μΩ·m ) |

| Magnetostriction coefficient | 27 λs (ppm) |

| Curie temperature | 410 Tc (℃) |

| Crystallization temperature | 535 Tx (℃) |

| Density | 7.18 ρ (g/cm3) |

| Hardness | 960 Hv (kg/mm2) |

| Thermal expansion coefficient | 7.6 (ppm/℃) |

Application

● Mid-frequency power transformer core, distribution transformer core

● Toroidal uncut cores for smooth filtered output inductors and differential mode input inductors for switching power supplies

● Noise suppression in car stereos, toroidal uncut cores for car navigation system chokes

● Ring-cut cores for PFC power factor correction in air conditioning and plasma TVs

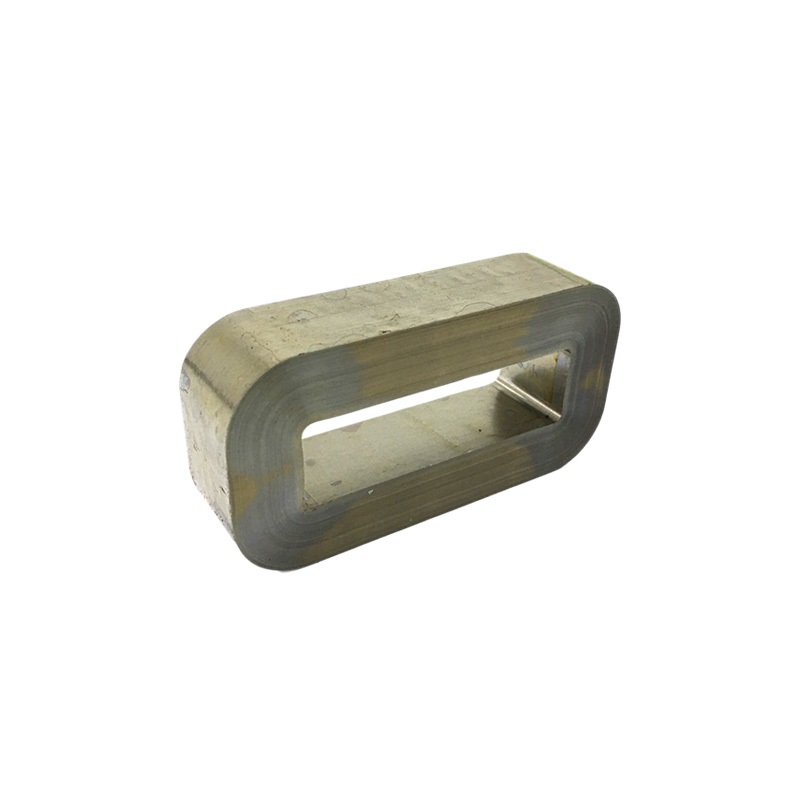

● High frequency rectangular cut cores for output inductors and transformers for switching power supplies, uninterruptible power supplies, etc.

● Toroidal, uncut cores for IGBTs, MOSFETs and GTOs pulse transformers

● High power density variable speed motors, stators and rotors for generators

Features

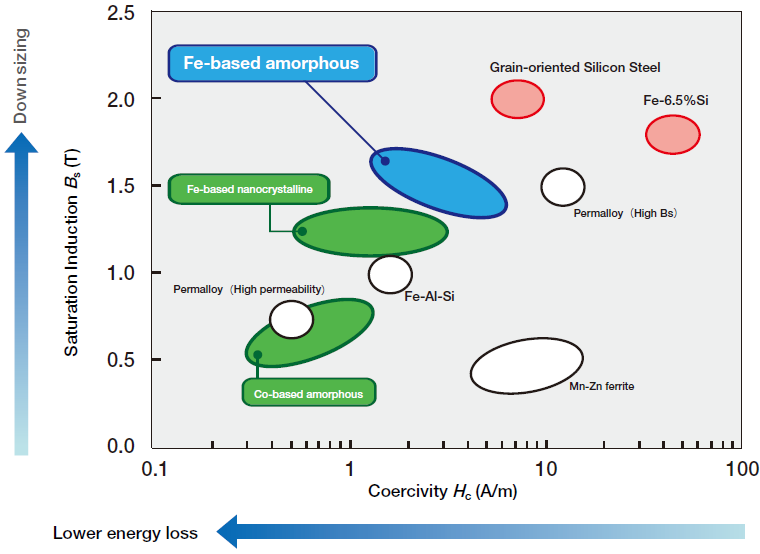

● Highest saturation magnetic induction among amorphous alloys-reduce components size

● Low coercivity- Improve components efficiency

● Variable Magnetic flux rate – By different core heat treatment processes to meet the requirements of different applications

● Good temperature stability- Can work at -55°C -130°C for long periods of time

● Cores used in transformers are 75% more energy efficient than S9 silicon steel cores in terms of no-load losses and 25% more energy °C efficient in terms of load losses

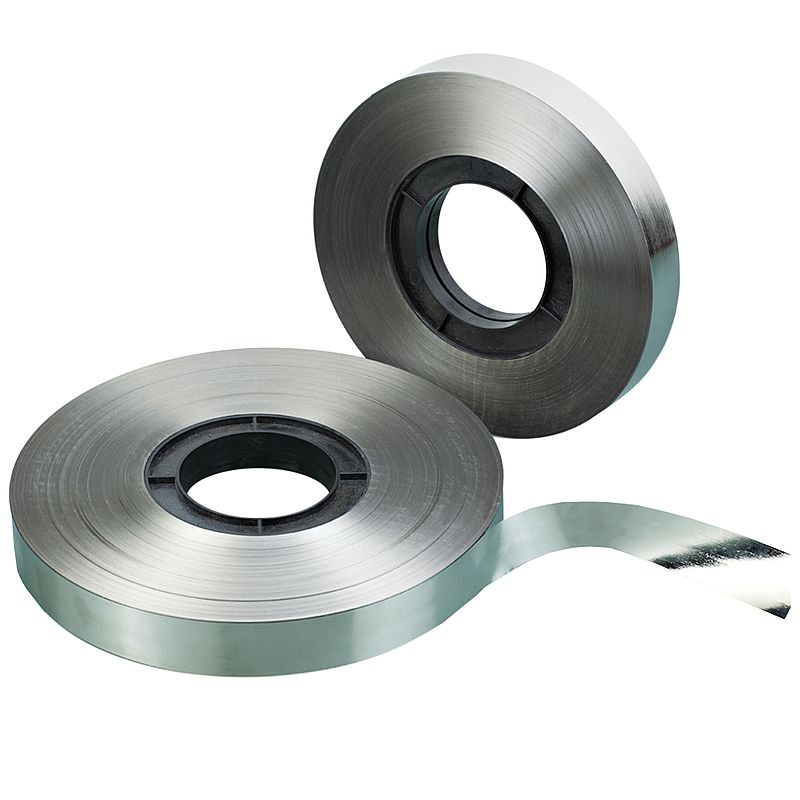

● Short strip production process and low production cost (see Fig. 1.1)

● The strip has a special microstructure which determines its excellent magnetic properties (Fig. 1.2) and performance stability.

● The composition and process parameters of the strip can be quickly adjusted to meet different usage requirements.

● For new energy solar grid-connected inverters

Figure 1.1 Amorphous ribbon production process

Figure 1.2 Bs versus Hc of different soft magnetic materials

Material comparison

| Performance Comparison of Fe-based amorphous alloys with cold-rolled silicon steel | ||

|

Basic parameters |

Fe-based amorphous alloys |

Cold-rolled silicon steel(0.2mm) |

| Saturation magnetic induction Bs (T) |

1.56 |

2.03 |

| Coercivity Hc (A/m) | 2.4 | 25 |

| Core losses(P400HZ/1.0T)(W/kg) | 2 | 7.5 |

| Core losses(P1000HZ/1.0T)(W/kg) | 5 | 25 |

| Core losses(P5000HZ/0.6T)(W/kg) | 20 | >150 |

| Core losses(P10000HZ/0.3T)(W/kg) | 20 | >100 |

| Maximum magnetic permeability (μm) | 45X104 | 4X104 |

| Resistivity (mW-cm) | 130 | 47 |

| Curie temperature(℃) | 400 | 740 |

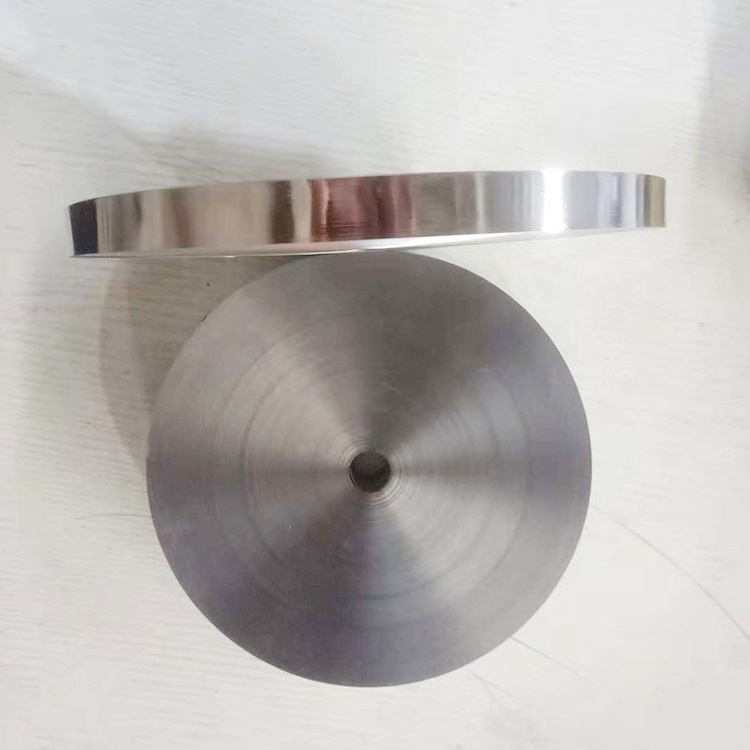

Product detail pictures:

Related Product Guide:

Sticking for the basic principle of "Super Top quality, Satisfactory service" ,We've been striving to be an excellent business enterprise partner of you for Hot Selling for Tft - Fe-Based 1K101 Amorphous Ribbon – Malio , The product will supply to all over the world, such as: Karachi, Rio de Janeiro, New Orleans, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!