According to the working design principle of the energy meter, it can be basically divided into 8 modules, power module, display module, storage module, sampling module, metering module, communication module, control module, MUC processing module. Each module performs its own duties by MCU processing module for unified integration and coordination, gluing into a whole.

1. Power module of energy meter

The power module of the power meter is the energy center for the normal operation of the power meter. The main function of the power module is to convert the high voltage of AC 220V into the DC low voltage power supply of DC12\DC5V\DC3.3V, which provides the working power supply for the chip and device of the other modules of the power meter. There are three types of power modules commonly used: transformers, resistance-capacitance step-down, and switching power supplies.

Transformer type: The AC 220 power supply is converted into AC12V through the transformer, and the required voltage range is reached in rectification, voltage reduction and voltage regulation. Low power, high stability, easy to electromagnetic interference.

Resistance-capacitance step-down power supply is a circuit that uses the capacitive reactance generated by a capacitor under a certain frequency of AC signal to limit the maximum operating current. Small size, low cost, small power, large power consumption.

Switching power supply is through the power electronic switching devices (such as transistors, MOS transistors, controllable thyristors, etc.), through the control circuit, so that the electronic switching devices periodically "on" and "off", so that the power electronic switching devices pulse modulation of the input voltage, so as to achieve voltage conversion and output voltage can be adjusted and automatic voltage regulation function. Low power consumption, small size, wide voltage range, high frequency interference, high price.

In the development and design of energy meters, according to the product function requirements, the size of the case, cost control requirements, national and regional policy requirements to determine what type of power supply.

2. Energy meter display module

The energy meter display module is mainly used for reading power consumption, and there are many types of display including digital tube, counter, ordinary LCD, dot matrix LCD, touch LCD, etc. The two display methods of digital tube and counter can only single display electricity consumption, with the development of smart grid, more and more types of electricity meters are required to display power data, digital tube and counter can not meet the process of intelligent power. LCD is the mainstream display mode in the current energy meter, according to the complexity of the display content in the development and design will choose different types of LCD.

3. Energy meter storage module

The energy meter storage module is used to store meter parameters, electricity, and historical data. Commonly used memory devices are EEP chip, ferroelectric, flash chip, these three kinds of memory chips have different applications in the energy meter. flash is a form of flash memory that stores some temporary data, load curve data, and software upgrade packages.

An EEPROM is a live erasable programmable read-only memory that allows users to erase and reprogram information stored in it either on the device or through a dedicated device, making an EEPROM useful in scenarios where data needs to be modified and updated frequently. EEPROM can be stored 1 million times and is used to store power data such as electricity quantity in the energy meter. The storage times can meet the storage times requirements of the energy meter in the entire life cycle, and the price is low.

Ferroelectric chip uses a characteristic of ferroelectric material to realize high-speed, low power consumption, high reliability data storage and logical operation, storage times of 1 billion; Data will not be emptied after power failure, which makes ferroelectric chips with high storage density, fast speed, and low energy consumption. Ferroelectric chips are mostly used in energy meters to store electricity and other power data, the price is higher, and it is only used in products that need to have high-frequency word storage requirements.

4, energy meter sampling module

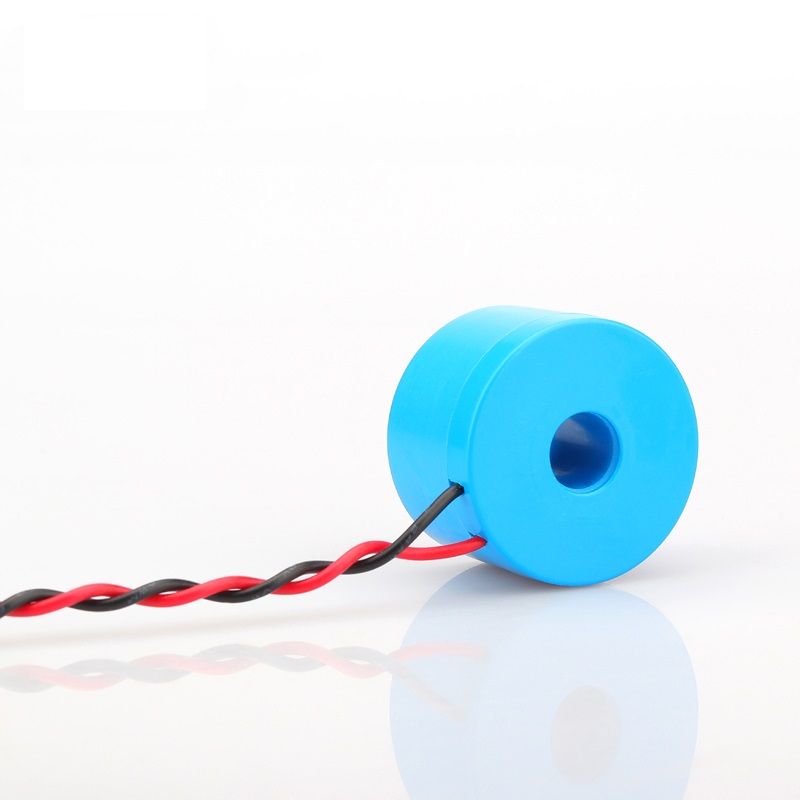

The sampling module of the watt-hour meter is responsible for converting the large current signal and the large voltage signal into the small current signal and the small voltage signal to facilitate the acquisition of the watt-hour meter. The current sampling devices commonly used are shunt, current transformer, Roche coil, etc., voltage sampling usually adopts high-precision resistance partial voltage sampling.

5, energy meter measurement module

The main function of the meter metering module is to complete the analog current and voltage acquisition, and convert the analog to digital; It can be divided into single-phase measurement module and three-phase measurement module.

6. Energy meter communication module

Energy meter communication module is the basis of data transmission and data interaction, the basis of smart grid data, intelligence, fine scientific management, and the basis of the development of the Internet of Things to achieve human-computer interaction. In the past, the lack of communication mode is mainly infrared, RS485 communication, with the development of communication technology, Internet of Things technology, the choice of energy meter communication mode has become extensive, PLC, RF, RS485, LoRa, Zigbee, GPRS, NB-IoT, etc. According to the different application scenarios and the advantages and disadvantages of each communication mode, the communication mode suitable for the market demand is selected.

7. Power meter control module

The power meter control module can control and manage the power load effectively. The common way is to install magnetic holding relay inside the power meter. Through power data, control scheme and real-time command, the power load is managed and controlled. The common functions in the energy meter are embodied in the over-current and overload disconnect relay to realize load control and line protection; Time control according to the time period to power on control; In the pre-paid function, the credit is insufficient to disconnect the relay; The remote control function is realized by sending commands in real time.

8, energy meter MCU processing module

The MCU processing module of the watt-hour meter is the brain of the watt-hour meter, which calculates all kinds of data, transforms and executes all kinds of instructions, and coordinates each module to achieve the function.

Energy meter is a complex electronic metering product, integrating multiple fields of electronic technology, power technology, power measurement technology, communication technology, display technology, storage technology and so on. It is necessary to integrate each functional module and each electronic technology to form a complete whole in order to give birth to a stable, reliable and accurate watt-hour meter.

Post time: May-28-2024