In the realm of electrical engineering and measurement, precision is paramount. One of the critical components that facilitate accurate current measurement is the shunt resistor. Among various materials used for shunts, Manganin stands out due to its unique properties. This article delves into what Manganin shunts are, the materials used for shunts, and their specific applications.

What is a Shunt?

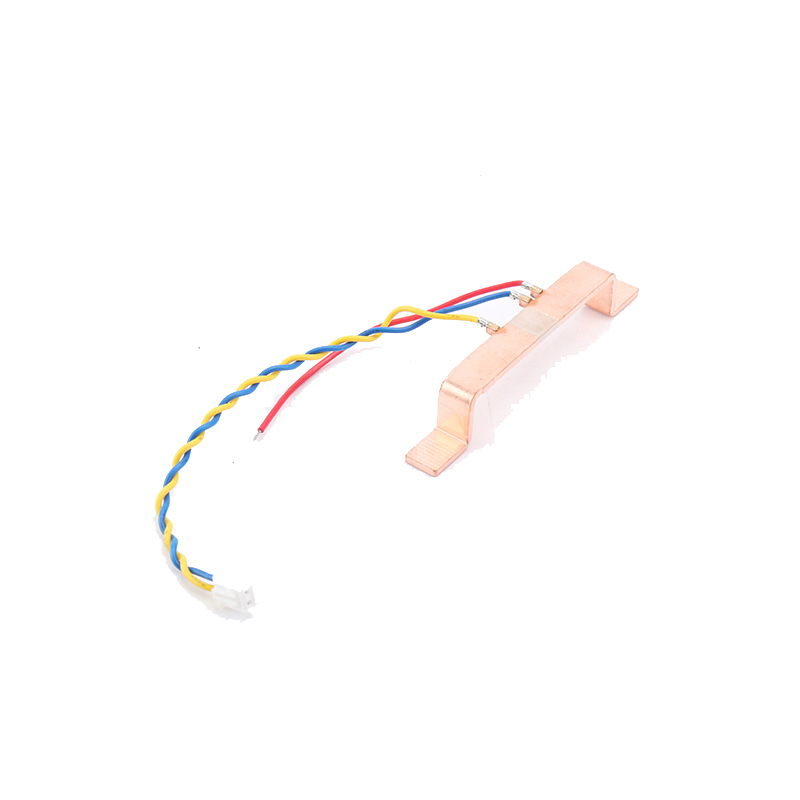

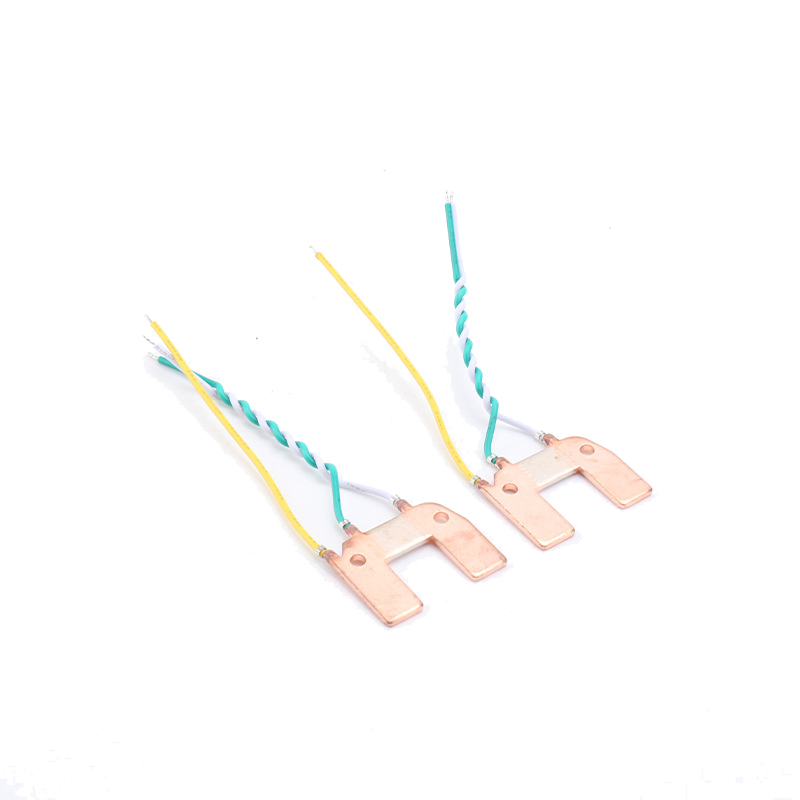

A shunt is a low-resistance component that is placed in parallel with a measuring device, such as an ammeter, to allow for the measurement of high currents without damaging the instrument. By using Ohm’s law, the voltage drop across the shunt can be measured, which is then used to calculate the current flowing through the circuit.

What Material is Used for Shunt?

Shunt resistors can be made from various materials, each offering distinct advantages and disadvantages. Common materials include:

Copper: Known for its excellent conductivity, copper is often used in low-current applications. However, its susceptibility to oxidation can lead to inaccuracies over time.

Nickel: Nickel shunts are durable and resistant to corrosion, making them suitable for harsh environments. However, they are not as conductive as copper.

Manganin: This is an alloy composed primarily of copper, manganese, and nickel. Manganin is particularly favored for shunt applications due to its low temperature coefficient of resistance, which means its resistance changes very little with temperature fluctuations. This stability is crucial for accurate measurements.

Constantan: Another alloy, primarily of copper and nickel, Constantan is often used in thermocouples and shunts due to its good stability and resistance to oxidation.

What is Manganin Shunt Used For?

Manganin shunts are widely used in various applications due to their unique properties. Here are some of the primary uses:

Precision Current Measurement: Manganin shunts are commonly employed in ammeters and other measuring devices where high accuracy is required. Their low temperature coefficient ensures that the resistance remains stable, providing reliable readings.

Calibration Standards: In laboratories, Manganin shunts are often used as calibration standards for other measuring instruments. Their predictable behavior under varying conditions makes them ideal for this purpose.

Power Measurement: In power systems, Manganin shunts are used to measure large currents without introducing significant voltage drops. This is essential for maintaining system efficiency and safety.

Industrial Applications: Manganin shunts are utilized in various industrial applications, including motor control systems and power distribution networks, where accurate current measurement is critical for operational efficiency.

Research and Development: In R&D settings, Manganin shunts are used in experimental setups where precise current measurements are necessary for data collection and analysis.

Conclusion

Manganin shunts represent a vital component in the field of electrical measurement. Their unique material properties, particularly their low temperature coefficient of resistance, make them ideal for applications requiring high accuracy and stability. Whether in industrial settings, laboratories, or power systems, Manganin shunts play a crucial role in ensuring that electrical measurements are both reliable and precise. As technology continues to advance, the importance of accurate current measurement will only grow, solidifying the role of Manganin shunts in modern electrical engineering.

Post time: Sep-25-2024