In the field of electrical engineering, transformers play a key role in the transmission and distribution of electrical energy. Among the various types of transformers, current transformers (CTs) are essential for measuring and monitoring current in power systems. A key component of these devices is the printed circuit board (PCB), which is central to the electrical connections and functionality of the current transformer. This article delves into the importance of PCBs in current transformers, exploring their design, function, and their impact on the overall performance of the device.

Understanding Current Transformers

Before we delve into the specifics of PCBs, it is necessary to first understand what a current transformer is. A current transformer is a transformer that produces a current that is reduced in proportion to the current in the primary circuit. This makes it safe to measure large currents, which can be dangerous to measure directly. Current transformers are widely used in power metering and protection systems to monitor the operation of power loads and protection relays.

The role of PCB in current transformer

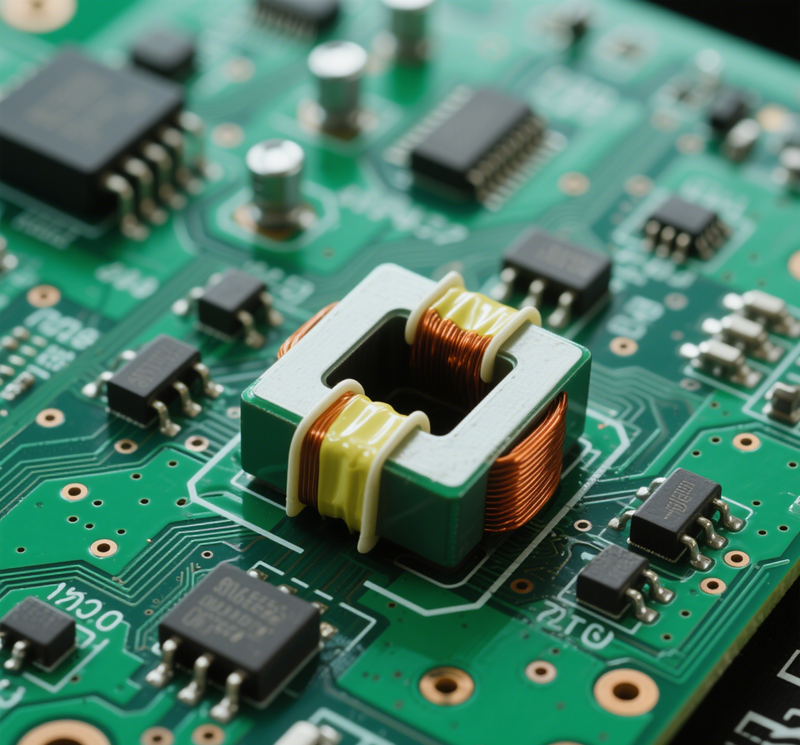

A printed circuit board (PCB) is a flat board made of insulating material with conductive pathways etched or printed on it. These pathways connect the various electronic components so that they can work together as a whole. In a current transformer, the PCB plays several key roles:

1. Electrical Connection

The main role of the PCB in a current transformer is to provide a platform for electrical connections. The PCB connects the primary and secondary windings of the transformer, as well as other components such as resistors, capacitors, and diodes. This connection is critical for accurate measurement of current and proper operation of the transformer.

2. Signal Processing

Current transformers often require signal conditioning to ensure the output is suitable for measurement and monitoring systems. The PCB can house various signal processing components, such as amplifiers and filters, to enhance the quality of the output signal. This processing is critical for applications that require high accuracy, such as protection relays and metering devices.

3. Thermal Management

Transformers generate heat during operation, and effective thermal management is critical to maintaining their performance and lifespan. PCBs can be designed with thermal management features, such as heat sinks or thermal vias, to dissipate heat away from sensitive components. This is particularly important for current transformers, where overheating can lead to inaccurate measurements or even failure.

4. Compact Design

Integrating components onto a PCB allows for a more compact current transformer design. This is particularly beneficial in applications where space is limited, such as switchgear or control panels. A well-designed PCB can minimize the overall size of the transformer while maintaining its performance, making it easier to install in a variety of environments.

5. Reliability and Durability

PCBs are manufactured with rugged materials that can withstand harsh environmental conditions. This durability is critical for current transformers, as they are often deployed outdoors or in industrial settings. A reliable PCB ensures that the current transformer operates effectively over its expected lifetime, reducing the need for maintenance and replacement.

Design the Current Transformer PCB

The design of a current transformer PCB requires consideration of several factors to ensure optimal performance. Here are some of the key factors that engineers must consider:

1.Component Selection

Selecting the right components is critical to the functionality of a current transformer. Engineers must choose components that can handle the expected current levels and environmental conditions. This includes choosing the right resistors, capacitors, and connectors that can withstand electrical and thermal stresses.

2. Layout and Routing

The PCB layout must be carefully planned to minimize interference and ensure efficient signal transmission. Proper trace routing is essential to reduce inductance and capacitance, which affect the accuracy of current measurement. In addition, component placement should facilitate effective thermal management.

3. Testing and Validation

Once the PCB design is manufactured, it must undergo rigorous testing to verify its performance. This includes checking electrical continuity, signal integrity, and thermal performance. Testing ensures that the current transformer will operate reliably under real-world conditions.

In conclusion

In summary, the printed circuit board (PCB) is a fundamental component of current transformers and plays a vital role in their functionality and performance. From providing electrical connections to enabling signal processing and thermal management, PCBs are an integral part of the operation of these devices. As technology continues to advance, the design and manufacturing of current transformer PCBs will also continue to evolve, resulting in more efficient and reliable current measurement solutions. For engineers and technicians in the field of electrical engineering, it is crucial to understand the importance of PCBs in current transformers as it directly affects the efficiency of power systems and the safety of electrical installations.

Post time: Apr-18-2025