Fe-based 1K101 Ribbon Amorphous ah

Sharaxaada

| Magaca Alaabta | Fe-based 1K101 Ribbon Amorphous ah |

| P/N | MLAR-2131 |

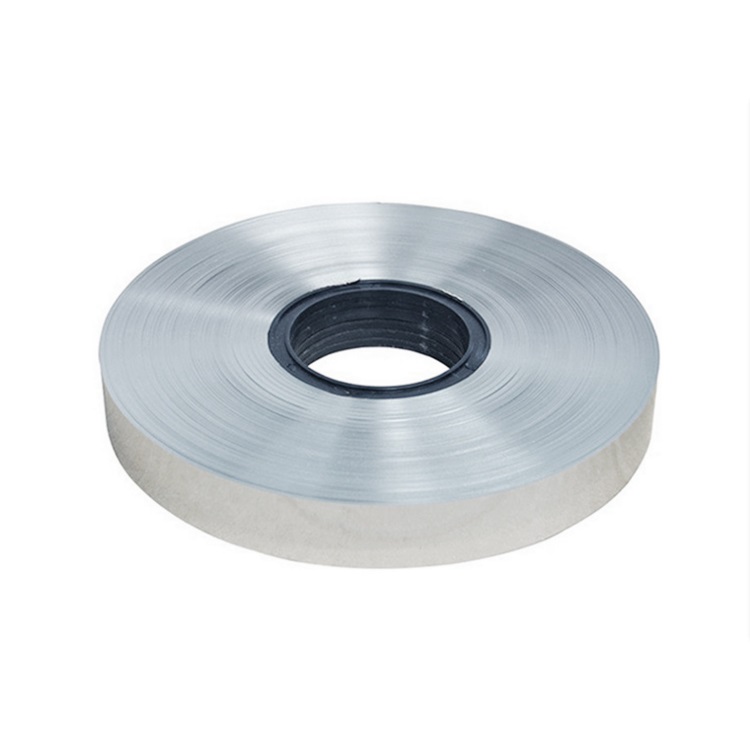

| Width | 5-80mm |

| Thicaqiidada | 25-35μm |

| Saturation magnetic induction | 1.56 Bs (T) |

| Qasab | 2.4 Hc (A/m) |

| iska caabin | 1.30 (μΩ·m) |

| Isku-dhafka Magnetostriction | 27 λs (ppm) |

| Heerkulka Curie | 410 Tc (℃) |

| Heerkulka crystallization | 535 Tx (℃) |

| Cufnaanta | 7.18 ρ (g/cm3) |

| Adag | 960 Hv (kg/mm2) |

| Isku xidhka balaadhinta kulaylka | 7.6 (pm/ ℃) |

Codsiga

● Xudunta koronto-dhaliyaha dhexe ee soo noqnoqda, xudunta beddelka qaybinta

● Koofiyadaha aan go'in ee Toroidal inductors-ka wax soo saarka si fudud loo sifeeyay iyo inductors-ga kala duwan ee beddelka sahayda korontada

● Xakamaynta qaylada ee stereos baabuurka, koofiyadaha aan go'in ee toroidal ee habka socodka baabuurka

● Koofiyadaha giraanta-garabka ah ee hagaajinta qodobka awoodda PFC ee qaboojiyaha iyo TV-yada balasmaha

● Xudunta goynta leydi-xagalka ah ee soo noqnoqda ee soo noqnoqda ee inductor-ka wax-soo-saarka iyo transformers-ka lagu beddelo sahayda korontada, sahayda korontada ee aan kala go'ayn, iwm.

● Toroidal, koofiyadaha aan goyn ee IGBTs, MOSFETs iyo GTOs transformers

● Matoorada xawaaraha doorsooma cufnaanta awooda sare, istators iyo rotors ee koronto dhaliyayaasha

Astaamaha

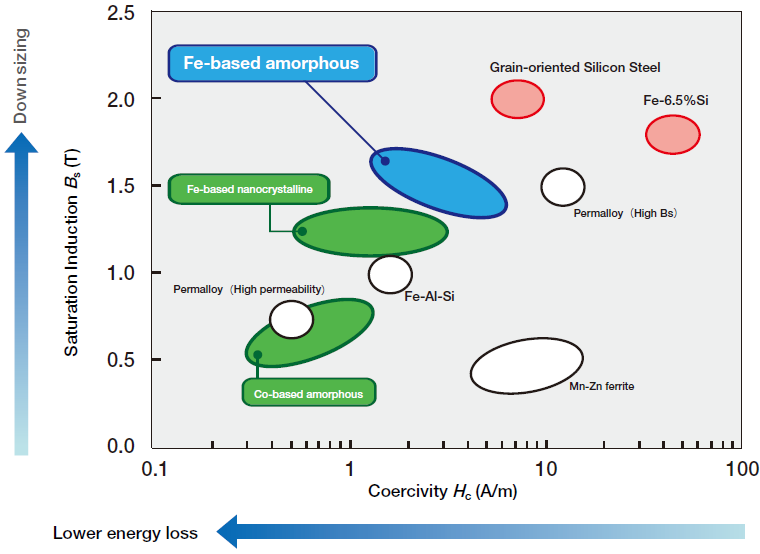

● Dheefta ugu sarraysa ee bini'aadamka ka dhex dhalata amorphous alloys-waxay yareeyaan cabbirka qaybaha

● Qasab hoose - Hagaajinta waxtarka qaybaha

● Heerka qulqulka magnetic isbedbeddelaya - Iyadoo loo marayo hababka daaweynta kulaylka asaasiga ah ee kala duwan si loo buuxiyo shuruudaha codsiyada kala duwan

● Dejinta heerkulka wanaagsan- Wuxuu ku shaqayn karaa -55°C -130°C mudo dheer

● Koofiyadaha loo isticmaalo transformers-ka ayaa 75% ka tamar badan marka loo eego S9 koofiyadaha birta silikoon marka la eego khasaaraha aan rarka lahayn iyo 25% ka badan tamar °C marka loo eego khasaaraha rarka

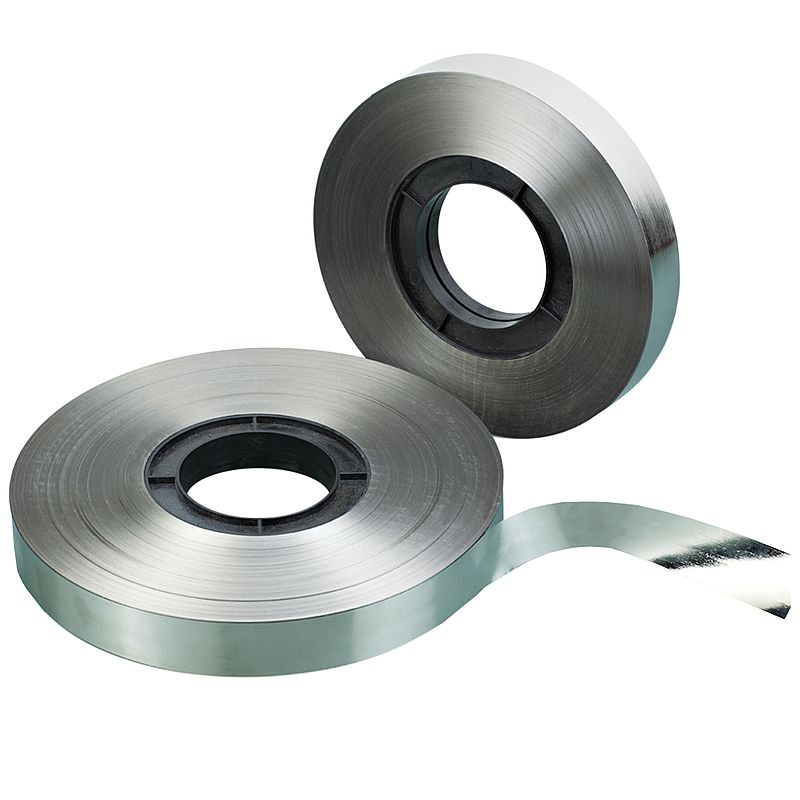

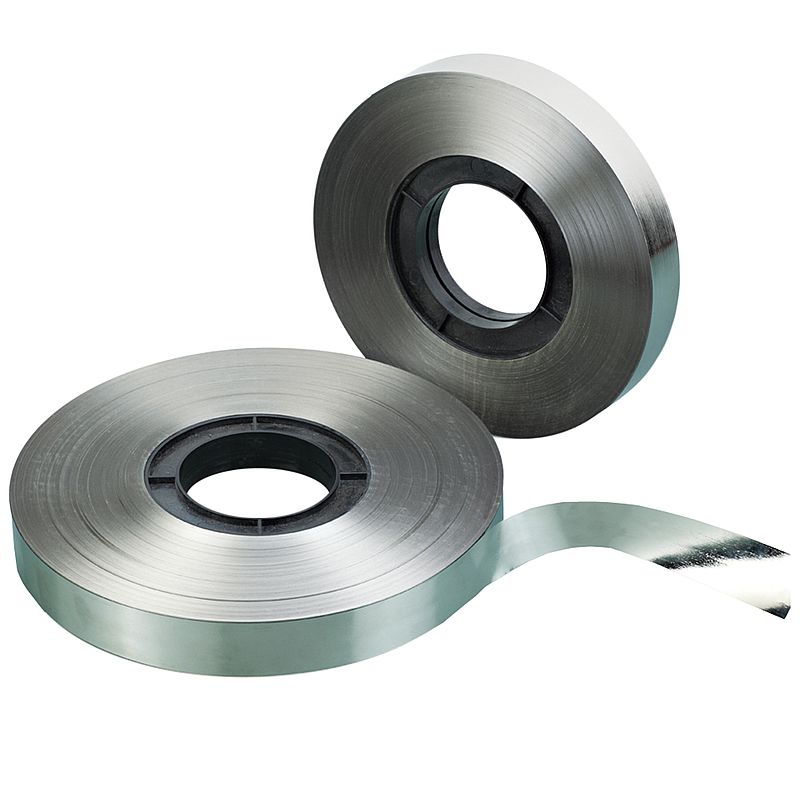

● Habka wax-soo-saarka xariijimaha gaaban iyo qiimaha wax-soosaarka oo hooseeya (eeg sawirka 1.1)

• Xariijimaha ayaa leh qaab-dhismeed yar oo gaar ah kaas oo go'aaminaya sifooyinka birlabeed ee wanaagsan (Jaantus. 1.2) iyo xasilloonida waxqabadka.

● Halbeegga iyo hab-raacyada xarriiqda si dhakhso ah ayaa loo hagaajin karaa si loo buuxiyo shuruudaha isticmaalka ee kala duwan.

● Wixii tamar cusub ah oo ku xiran koronto-rogayaasha

Jaantuska 1.1 Habka wax-soo-saarka ribbon-ka-muuqaalka ah

Jaantuska 1.2 Bs iyo Hc ee agabka birlabeedka jilicsan ee kala duwan

Isbarbardhigga walxaha

| Isbarbardhigga Waxqabadka ee Alloys Amorphous-ku-salaysan oo leh bir silikoon-duuban oo qabow | ||

| Halbeegyada aasaasiga ah | Alloys amorphous-ku-salaysan | bir silikoon ah oo qabow-duuban (0.2mm) |

| Soodhaweynta birlabeedka Bs (T) | 1.56 | 2.03 |

| Qasab Hc (A/m) | 2.4 | 25 |

| Khasaaraha asaasiga ah(P400HZ/1.0T) (W/kg) | 2 | 7.5 |

| Khasaaraha asaasiga ah(P1000HZ/1.0T)(W/kg) | 5 | 25 |

| Khasaaraha asaasiga ah(P5000HZ/0.6T)(W/kg) | 20 | >150 |

| Khasaaraha asaasiga ah(P10000HZ/0.3T)(W/kg) | 20 | >100 |

| Dareemida magnetic ugu badan (μm) | 45X104 | 4X104 |

| Iska caabin (mW-cm) | 130 | 47 |

| Heerkulka Curie(℃) | 400 | 740 |