Marka loo eego mabda'a naqshadeynta shaqada ee mitirka tamarta, asal ahaan waxaa loo qaybin karaa 8 qaybood, module awood, module bandhig, module kaydinta, module muunad, module mitir, module isgaarsiinta, module gacanta, module processing MUC. Cutub kastaa waxa uu fuliyaa waajibaadkiisa iyada oo loo marayo moduleka habaynta ee MCU ee is dhexgalka iyo isuduwidda midaysan, isaga oo ku dheggan guud ahaan.

1. Module awoodda mitirka tamarta

Qalabka korantada ee mitirka korontadu waa xarunta tamarta ee hawlgalka caadiga ah ee mitirka korontada. Shaqada ugu weyn ee moduleka korantadu waa in loo beddelo tamarta sare ee AC 220V oo loo beddelo awoodda korantada hoose ee DC ee DC12 \ DC5V \ DC3.3V, taas oo bixisa tamarta shaqada ee chip iyo aaladda qaybaha kale ee mitirka korantada. Waxaa jira saddex nooc oo ah modules-koronto oo inta badan la isticmaalo: Transformers, awoodda iska caabinta hoos-u-dhigga, iyo beddelka sahayda korontada.

Nooca Transformer-ka: Awoodda AC 220 waxa loo beddelaa AC12V iyada oo loo marayo Transformer-ka, tirada korantada ee loo baahan yahayna waxaa lagu gaarayaa hagaajinta, dhimista korantada iyo nidaaminta korantada. Awood hoose, xasillooni sare, fududahay faragelinta elektromagnetic.

Awood-iska-caabbinta hoos-u-soo-saarka korontadu waa wareeg adeegsata fal-celinta awoodda leh ee uu dhaliyo kapacitor hoos yimaada inta jeer ee calaamadda AC si loo xaddido ugu badnaan hawlgalka hadda socda. Cabbir yar, qiimo jaban, koronto yar, isticmaalka koronto oo weyn.

Korontada wareejinta waa iyada oo loo marayo aaladaha beddelka elektiroonigga ah ee korantada (sida transistor-ka, MOS transistors, thyristors la koontarooli karo, iwm.), iyada oo loo marayo wareegga kontoroolka, si aaladaha wareejinta elektiroonigga ah ay xilliyada qaarkood "shidaan" iyo "off", si markaa qalabka elektarooniga ah ee beddelka qalabka garaaca garaaca korantada gashada, si loo gaaro beddelka korantada iyo korantada wax soo saarka waa la hagaajin karaa iyo shaqeynta xakamaynta korantada si toos ah. Isticmaalka tamarta hoose, cabbir yar, kala duwanaanta tamarta ballaaran, faragelinta soo noqnoqda sare, qiimaha sare.

Horumarinta iyo naqshadeynta mitirka tamarta, marka loo eego shuruudaha shaqada alaabta, xajmiga kiiska, shuruudaha xakamaynta kharashka, shuruudaha siyaasadda qaranka iyo gobolka si loo go'aamiyo nooca korontada.

2. Module bandhigay mitirka tamarta

Module-ka soo bandhiga mitirka tamarta waxaa inta badan loo isticmaalaa akhrinta isticmaalka tamarta, waxaana jira noocyo badan oo bandhig ah oo ay ku jiraan tuubo dhijitaal ah, miiska, caadiga ahLCD, Dhibcaha matrix LCD, LCD taabasho, iwm. Labada hab bandhigay ee tube digital iyo counter kaliya hal bandhig isticmaalka korontada, iyadoo horumarinta grid smart, noocyo badan oo ka mid ah mitir koronto ayaa loo baahan yahay si ay u muujiyaan xogta awoodda, tube digital iyo counter aan la kulmi karin habka awoodda caqliga leh. LCD waa qaabka guud ee bandhiga mitirka tamarta hadda, marka loo eego kakanaanta nuxurka bandhigga ee horumarinta iyo naqshadeynta waxay dooran doontaa noocyo kala duwan oo LCD ah.

3. module kaydinta mitirka tamarta

Habka kaydinta mitirka tamarta waxaa loo isticmaalaa in lagu kaydiyo cabbirka mitirka, korontada, iyo xogta taariikhiga ah. Aaladaha xusuusta ee sida caadiga ah loo isticmaalo waa EEP chip, ferroelectric, flash chip, saddexdan nooc ee chip-yada xusuusta ayaa leh codsiyo kala duwan oo mitirka tamarta ah. flash waa nooc ka mid ah xusuusta flashka ee kaydisa xog ku meel gaar ah, xogta qalooca, iyo xidhmooyinka casriyaynta software.

EEPROM waa xasuus si toos ah loo tirtiri karo oo la akhrin karo oo keliya taasoo u oggolaanaysa dadka isticmaala inay tirtiraan oo dib u habeeyaan macluumaadka ku kaydsan aaladda ama qalab gaar ah, taasoo ka dhigaysa EEPROM mid faa'iido u leh xaaladaha halkaas oo xogta loo baahan yahay in wax laga beddelo oo la cusbooneysiiyo si joogto ah. EEPROM waxa la kaydin karaa 1 milyan jeer waxaana loo isticmaalaa in lagu kaydiyo xogta tamarta sida tirada korantada ee mitirka tamarta. Waqtiyada kaydinta waxay buuxin karaan shuruudaha wakhtiyada kaydinta ee mitirka tamarta ee wareegga nolosha oo dhan, qiimuhuna waa yar yahay.

Chip Ferroelectric wuxuu isticmaalaa sifo ka mid ah walxaha ferroelectric si loo ogaado xawaaraha sare, isticmaalka tamarta hooseeya, kaydinta xogta kalsoonida sare iyo hawlgalka macquulka ah, waqtiyada kaydinta 1 bilyan; Xogta lama faaruqi doono ka dib markii korontadu xumaato, taas oo ka dhigaysa ferroelectric chips cufnaanta kaydinta sare, xawaaraha degdega ah, iyo isticmaalka tamarta hoose. Chips Ferroelectric waxaa inta badan loo isticmaalaa mitirka tamarta si loo kaydiyo korantada iyo xogta kale ee tamarta, qiimuhu waa ka sarreeyaa, waxaana loo isticmaalaa oo kaliya alaabooyinka u baahan in ay helaan shuruudaha kaydinta erayada soo noqnoqda.

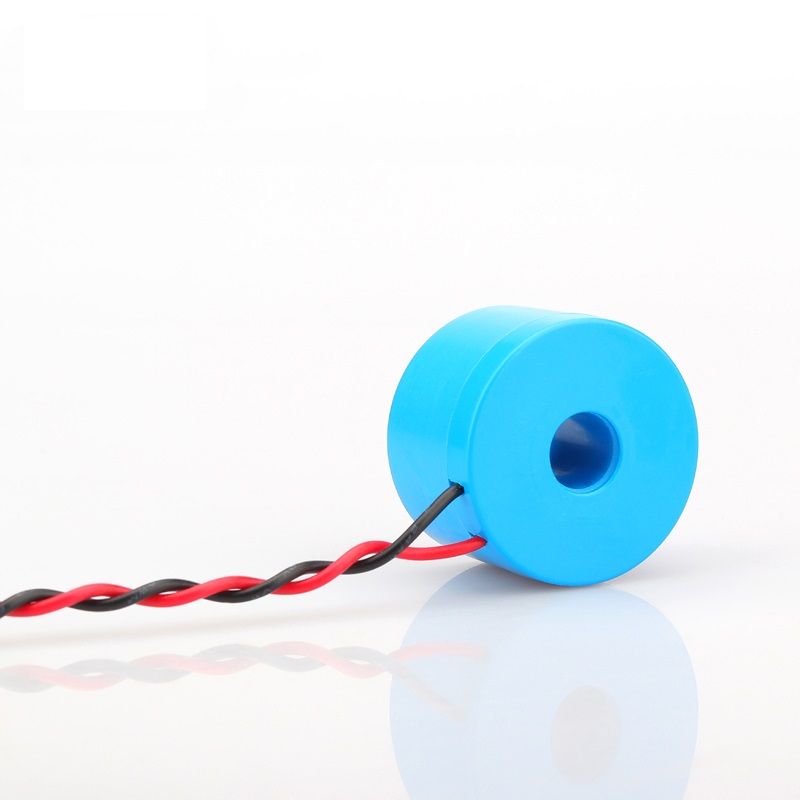

4, module muunad mitir tamarta

Qaybta muunada ee mitirka watt-saac ayaa mas'uul ka ah u beddelka calaamadda weyn ee hadda jirta iyo calaamadda korantada weyn ee calaamadda hadda jirta iyo calaamadda korantada yar si ay u fududayso helitaanka mitirka watt-saac. Qalabka muunada ee hadda la isticmaalo waashunt, Transformer hadda, Roche gariiradda, iwm., Muunad danab sida caadiga ah qaadanaysaa-sax-sax-sax-sax-sax iska caabin qayb qayb.

5, moduleka cabbiraadda mitirka tamarta

Hawsha ugu weyn ee cutubka cabbiraadda mitirku waa in la dhammaystiro helitaanka hadda analogga ah iyo korantada, oo loo beddelo analoogga dhijitaalka ah; Waxaa loo qaybin karaa moduleka cabbiraadda hal-waji iyo module cabbir saddex-waji ah.

6. moduleka isgaarsiinta mitirka tamarta

Module isgaarsiinta mitirka tamarta waa saldhigga gudbinta xogta iyo isdhexgalka xogta, saldhigga xogta grid smart, sirdoonka, maaraynta sayniska wanaagsan, iyo saldhigga horumarinta internetka ee Waxyaabaha si loo gaaro isdhexgalka aadanaha iyo kombiyuutarka. Waagii hore, la'aanta hab isgaarsiinta inta badan waa infrared, isgaarsiinta RS485, iyadoo horumarinta technology isgaarsiinta, Internet of technology, doorashada ee habka isgaarsiinta mitir tamarta noqday ballaaran, PLC, RF, RS485, LoRa, Zigbee, GPRS, NB-IoT, iwm Marka loo eego xaaladaha codsiga kala duwan iyo shuruudaha isgaarsiinta ee hab kasta oo la doortay iyo faa'iidooyinka iyo faa'iidooyinka suuqa la doortay.

7. module kontoroolka mitirka korontada

Qaybta kontoroolka mitirka korontadu waxay xakamayn kartaa oo u maarayn kartaa culayska korantada si wax ku ool ah. Habka caadiga ah waa in lagu rakibo gudbinta xajinta magnetka gudaha mitirka korontada. Iyada oo loo marayo xogta korantada, nidaamka xakamaynta iyo amarka waqtiga-dhabta ah, culayska korantada waa la maareeyaa oo la xakameeyaa. Hawlaha caadiga ah ee mitirka tamarta waxay ka kooban yihiin isku-xidhka-celinta xad-dhaafka ah iyo culeyska xad-dhaafka ah si loo xaqiijiyo xakamaynta rarka iyo ilaalinta khadka; Xakamaynta waqtiga iyada oo loo eegayo muddada wakhtiga awoodda lagu xakameynayo; Shaqada horay loo bixiyay, creditku kuma filna in la gooyo isku-gudbinta; Hawsha kontoroolka fogfog waxa lagu xaqiiqsadaa in la diro amarrada wakhtiga dhabta ah.

8, mitir tamarta MCU module processing

Habka farsamaynta ee MCU ee mitirka watt-hour waa maskaxda mitirka watt-saac, kaas oo xisaabiya dhammaan noocyada xogta, beddela oo fulisa dhammaan noocyada tilmaamaha, oo isku duwo module kasta si uu u gaaro shaqada.

Mitirka tamarta waa sheyga cabbiraadda elektiroonigga ah ee adag, isku-dhafan dhinacyo badan oo tignoolajiyada elektiroonigga ah, tignoolajiyada korantada, tignoolajiyada cabbiraadda awoodda, tignoolajiyada isgaarsiinta, tignoolajiyada bandhigga, tignoolajiyada kaydinta iyo wixii la mid ah. Waa lagama maarmaan in la isku daro module kasta oo shaqeynaya iyo tignoolajiyad kasta oo elektaroonig ah si loo sameeyo dhammaystir dhammaystiran si ay u dhalato xasilloon, la isku halleyn karo oo mitir saacad-watt ah oo sax ah.

Waqtiga boostada: Meey-28-2024