Fe-Based 1K101 Amorphous Ribbon

Tlhaloso

| Lebitso la Sehlahiswa | Fe-Based 1K101 Amorphous Ribbon |

| P/N | MLAR-2131 |

| Bopharath | 5-80mm |

| Thickness | 25-35μm |

| Saturation magnetic induction | 1.56 Bs (T) |

| Ho qobella | 2.4 Hc (A/m) |

| Ho hanyetsa | 1.30 (μΩ·m) |

| Magnetostriction coefficient | 27 λs (ppm) |

| Mocheso oa curie | 410 Tc (℃) |

| Mocheso oa Crystallization | 535 Tx (℃) |

| Botenya | 7.18 ρ (g/cm3) |

| Ho thatafala | 960 Hv (kg/mm2) |

| Coefficient ea ho eketsa mocheso | 7.6 (ppm/℃) |

Kopo

● Mid-frequency power transformer core, kabo ea motlakase ea motlakase

● Li-cores tsa Toroidal uncut bakeng sa li-inductors tse hloekisitsoeng hantle le li-inductors tsa mefuta e fapaneng bakeng sa ho fetola lisebelisoa tsa motlakase.

● Khatello ea lerata li-stereo tsa koloi, li-cores tsa toroidal tse sa khaoletsoang bakeng sa tsamaiso ea ho tsamaea ea koloi

● Li-ring-cut cores bakeng sa tokiso ea matla a PFC moeeng le li-TV tsa plasma

● Li-cores tse sehiloeng ka makhetlo a mangata bakeng sa li-inductors le li-transformer bakeng sa ho chencha lisebelisoa tsa motlakase, lisebelisoa tsa motlakase tse sa senyeheng, joalo-joalo.

● Toroidal, uncut cores bakeng sa IGBTs, MOSFETs le GTOs pulse transformer

● Li-motors tsa lebelo tse fapaneng tsa matla a phahameng, li-stator le li-rotor bakeng sa lijenereithara

Likaroloana

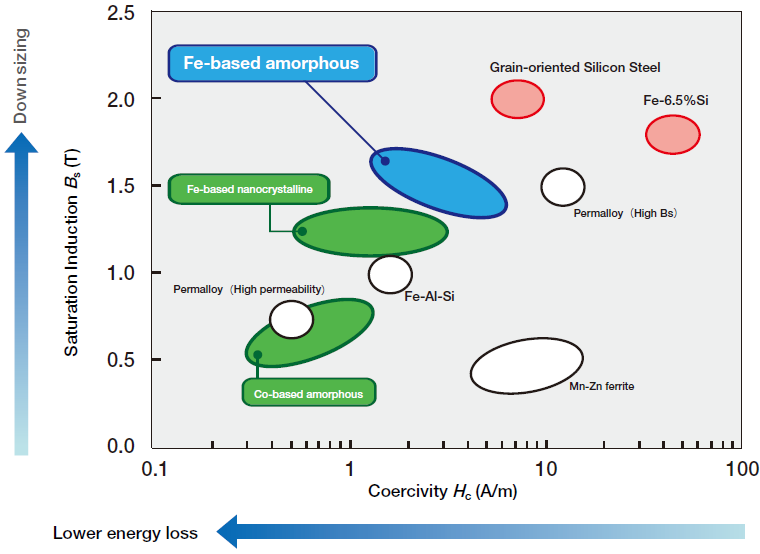

● Phahameng ka ho fetisisa saturation magnetic induction har'a amorphous alloys-fokotsa likarolo boholo

● Coercivity e tlase- Ntlafatsa bokhoni ba likarolo

● Sekhahla se feto-fetohang sa Magnetic flux - Ka mekhoa e fapaneng ea kalafo ea mocheso oa mantlha ho fihlela litlhoko tsa lits'ebetso tse fapaneng

● Ho tsitsisa hantle ha mocheso- E ka sebetsa ho -55°C -130°C ka nako e telele

● Li-cores tse sebelisoang ho li-transformer li sebetsa hantle ka 75% ho feta li-cores tsa tšepe tsa silicon tsa S9 ho latela tahlehelo e sa jeleng thepa le matla a fetang 25% °C ho latela tahlehelo ea mojaro.

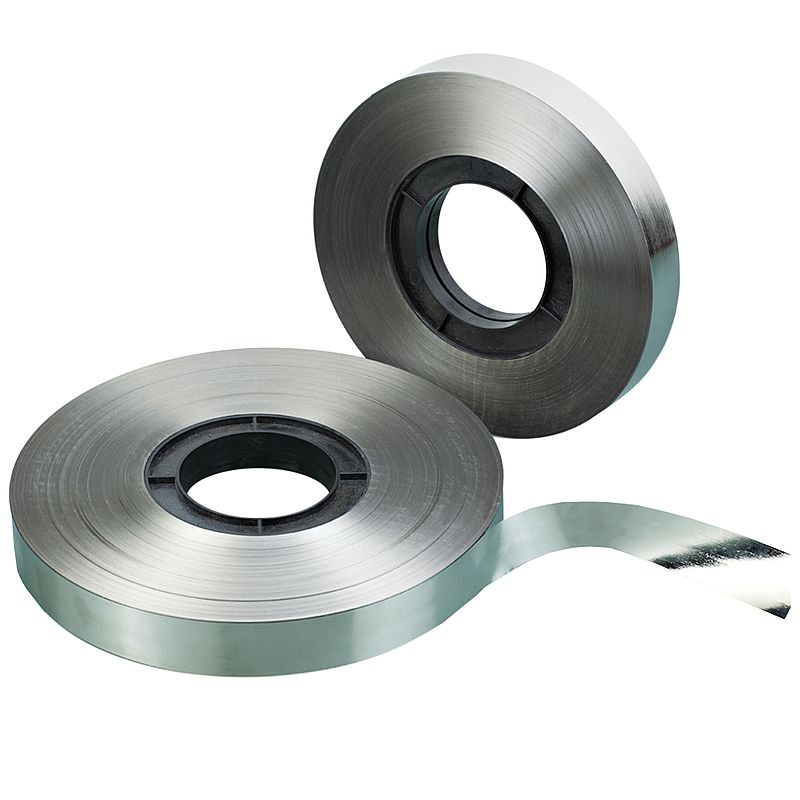

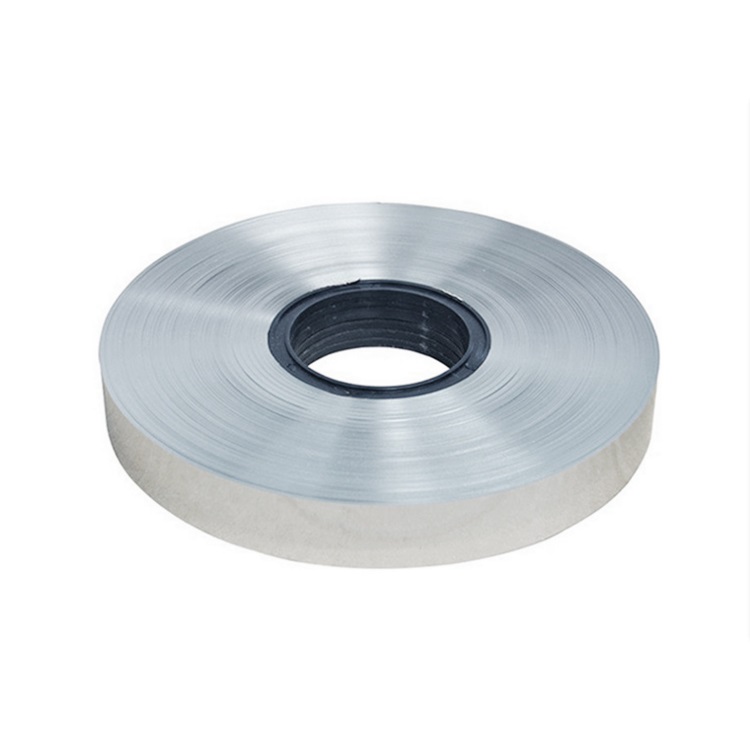

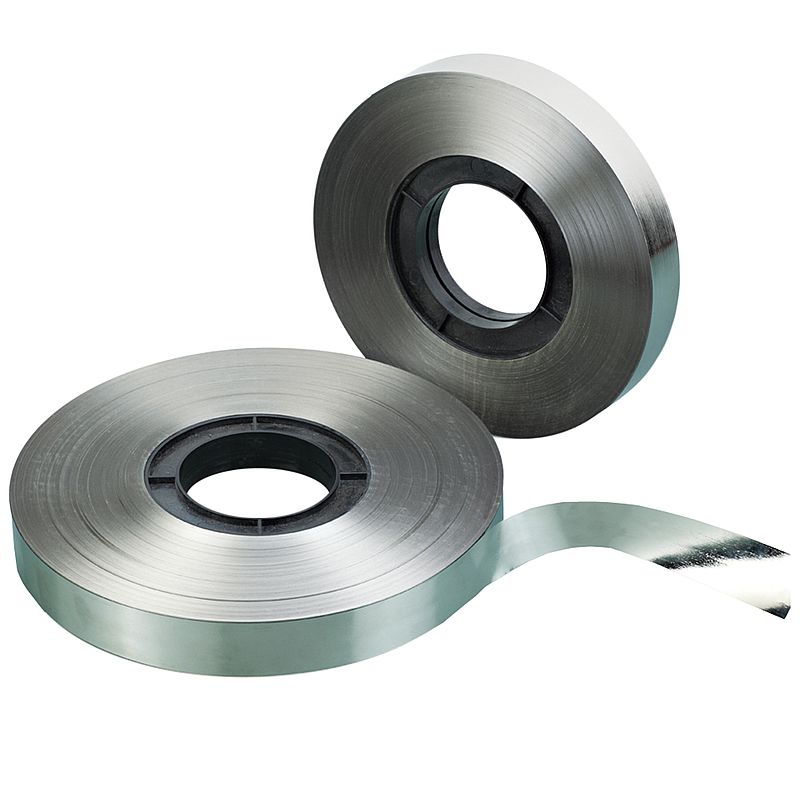

● Ts'ebetso e khutšoane ea tlhahiso ea li-strip le litšenyehelo tse tlase tsa tlhahiso (sheba setšoantšo sa 1.1)

● The hlobolisa e na le microstructure e khethehileng e khethollang litšobotsi tsa eona tse babatsehang tsa makenete (setšoantšo sa 1.2) le botsitso ba ts'ebetso.

● Sebopeho le mekhoa ea ts'ebetso ea sekhahla se ka fetoloa kapele ho finyella litlhoko tse fapaneng tsa tšebeliso.

● Bakeng sa li-inverters tse hoketsoeng ke grid ea letsatsi tse ncha

Setšoantšo sa 1.1 Ts'ebetso ea tlhahiso ea ribone ea Amorphous

Setšoantšo sa 1.2 Bs khahlano le Hc ea lisebelisoa tse fapaneng tse bonolo tsa makenete

Papiso ea lintho tse bonahalang

| Ts'ebetso Papiso ea li-alloys tsa amorphous Fe-based tse nang le tšepe ea silicon e batang | ||

| Litekanyetso tsa motheo | Li-alloys tsa amorphous tse thehiloeng ho Fe | Tšepe ea silicon e batang (0.2mm) |

| Saturation magnetic induction Bs (T) | 1.56 | 2.03 |

| Coercivity Hc (A/m) | 2.4 | 25 |

| Litahlehelo tsa mantlha(P400HZ/1.0T)(W/kg) | 2 | 7.5 |

| Litahlehelo tsa mantlha(P1000HZ/1.0T)(W/kg) | 5 | 25 |

| Litahlehelo tsa mantlha(P5000HZ/0.6T)(W/kg) | 20 | ~150 |

| Litahlehelo tsa mantlha(P10000HZ/0.3T)(W/kg) | 20 | ~100 |

| Boholo ba ho kenella ha makenete (μm) | 45X104 | 4X104 |

| Resistivity (mW-cm) | 130 | 47 |

| Thempereichara ea curie(℃) | 400 | 740 |