- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Fe-Based 1K101 Amorphous Ribbon

Inkcazo

| Igama lemveliso | Fe-Based 1K101 Amorphous Ribbon |

| P/N | I-MLAR-2131 |

| Ububanzith | 5-80mm |

| Thiubunyani | 25-35μm |

| Ukufakwa kwemagnethi yokugcwalisa | 1.56 Bs (T) |

| Ukunyanzeliswa | 2.4 Hc (A/m) |

| Ukuxhathisa | 1.30 (μΩ·m) |

| I-Magnetostriction coefficient | 27 λs (ppm) |

| Ubushushu beCurie | 410 Tc (℃) |

| Ubushushu beCrystallization | 535 Tx (℃) |

| Ukuxinana | 7.18 ρ (g/cm3) |

| Ukuqina | 960 Hv (kg/mm2) |

| I-coefficient yokwandisa i-Thermal | 7.6 (ppm/℃) |

Isicelo

● I-Mid-frequency power transformer core, i-core transformer yokusabalalisa

● I-Toroidal uncut cores ye-inductors egudileyo ehluziweyo kunye ne-inductors yemowudi eyahlukileyo yokutshintsha izixhobo zombane.

● Ukucutha ingxolo kwiistereo zemoto, ii-toroidal uncut cores zenkqubo yokukhangela imoto eziminxeka

● I-ring-cut cut cores ye-PFC power factor correction in air conditioning and plasma TVs

● I-high frequency cut rectangular cut cores yee-inductors eziphumayo kunye ne-transformer zokutshintsha izixhobo zombane, unikezelo lwamandla olungaphazamisekiyo, njl.

● Toroidal, uncut cores for IGBTs, MOSFETs kunye neGTOs pulse transformers

● Uxinaniso lwamandla ombane oguquguqukayo oguquguqukayo lweemotor, i-stators kunye ne-rotors yeejeneretha

Iimbonakalo

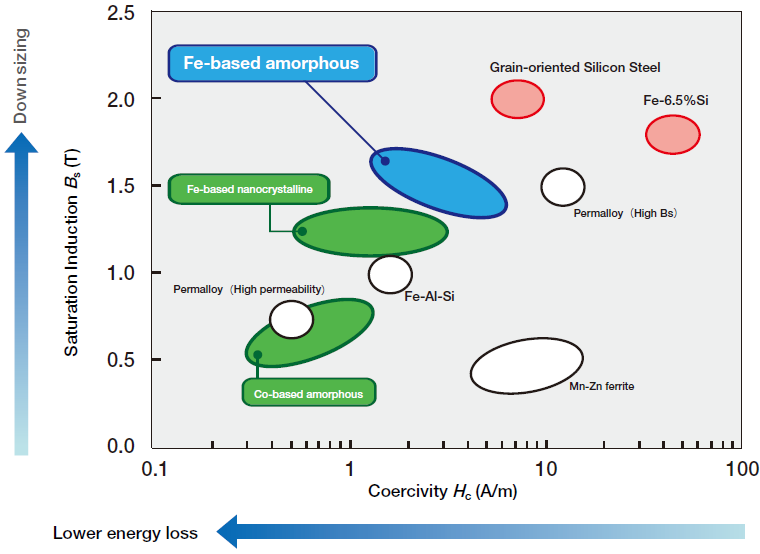

● Elona nqanaba liphezulu lokungeniswa kwemagnethi phakathi kwealloyi ze-amorphous-ukunciphisa ubungakanani bamalungu

● Ukunyanzeliswa okuphantsi- Ukuphucula ukusebenza kakuhle kwamalungu

● Iqondo lokuguquguquka kweMagnetic eguquguqukayo - Ngeenkqubo ezahlukeneyo zokunyanga ubushushu obungundoqo ukuhlangabezana neemfuno zezicelo ezahlukeneyo

● Uzinzo oluhle lobushushu- Inokusebenza kwi -55°C -130°C ixesha elide

● Iicores ezisetyenziswa kwiziguquli zisebenza ngamandla ngama-75% ngaphezulu kune-S9 silicon cores yentsimbi ngokumalunga nelahleko ekungalayishwanga kuyo kunye ne-25% ngaphezulu kwamandla °C ngokufanelekileyo ngokwelahleko yomthwalo.

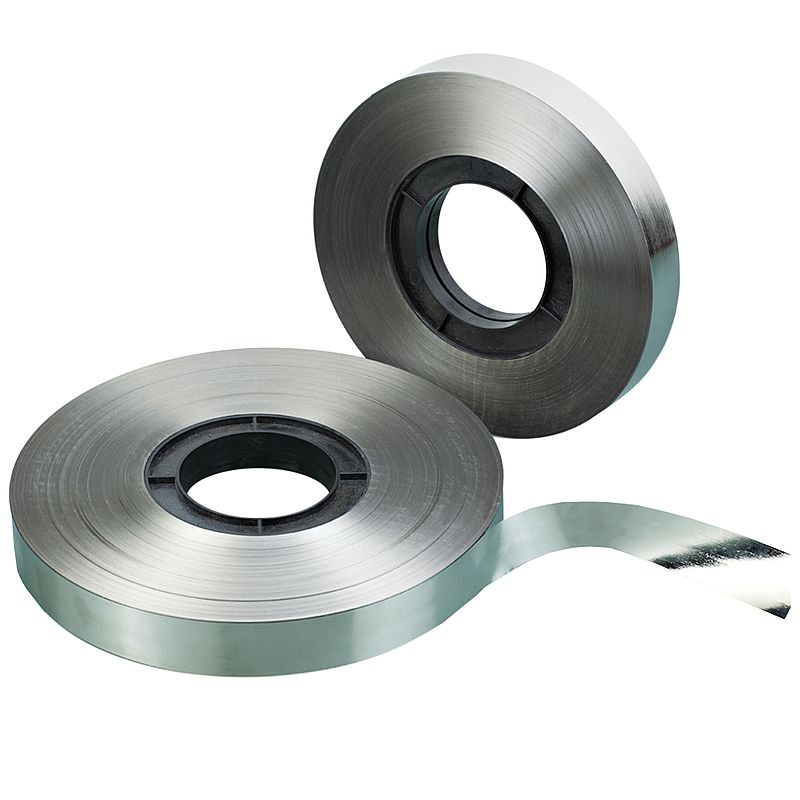

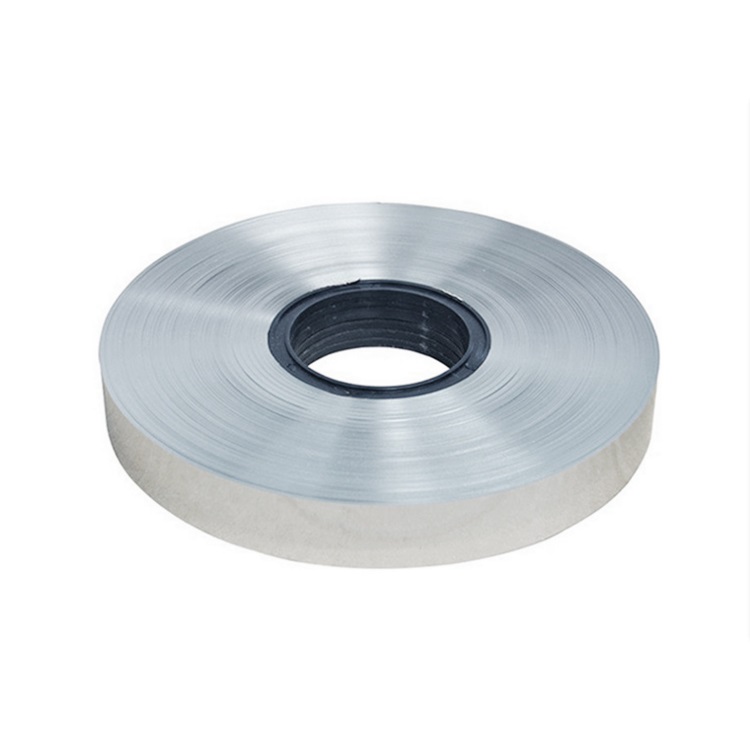

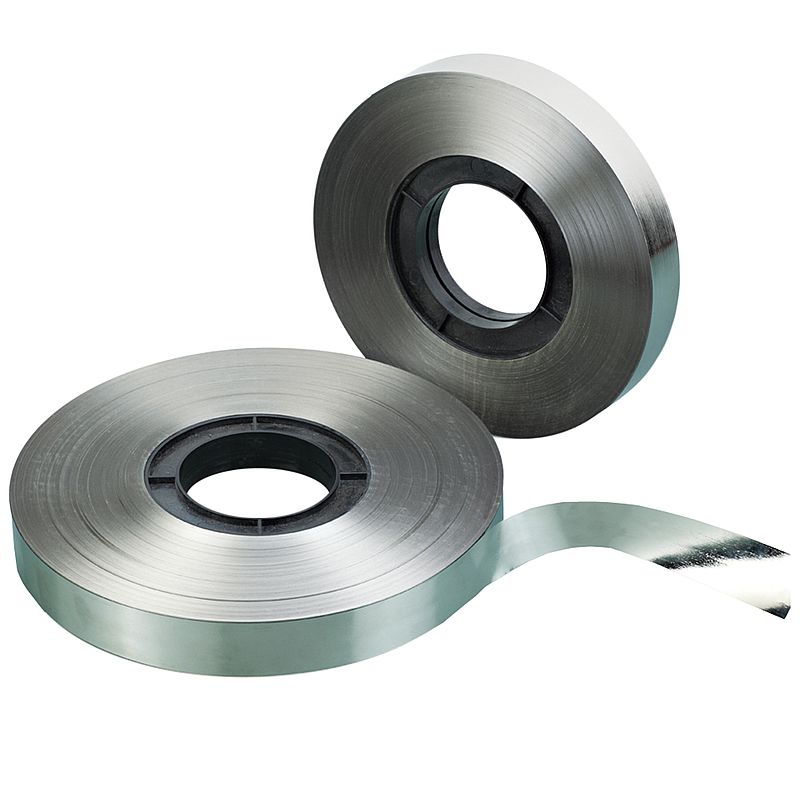

● Inkqubo yokuvelisa imicu emifutshane kunye nexabiso eliphantsi lokuvelisa (jonga umzobo 1.1)

● I-strip ine-microstructure ekhethekileyo emisela iimpawu zayo ezibalaseleyo zamagnetic (Umfanekiso 1.2) kunye nokuzinza komsebenzi.

● Ukuqulunqwa kunye neeparamitha zenkqubo yomgca unokulungiswa ngokukhawuleza ukuhlangabezana neemfuno ezahlukeneyo zokusetyenziswa.

● Ukufumana ii-inverters eziqhagamshelwe kwigridi yelanga yamandla amatsha

Umzobo 1.1 Inkqubo yokuveliswa kweribhoni ye-Amorphous

Umfanekiso 1.2 Bs ngokuchasene ne-Hc yezinto ezahlukeneyo ezithambileyo zemagnethi

Uthelekiso lwezinto

| Ukuthelekiswa kokuSebenza kwee-alloys ze-amorphous ezisekelwe kwi-Fe-based kunye nentsimbi ye-silicon epholileyo | ||

| Iiparamitha ezisisiseko | Ii-alloys ezisekelwe kwi-amorphous | Intsimbi yesilicon epholileyo eqengqelekayo (0.2mm) |

| I-Saturation magnetic induction Bs (T) | 1.56 | 2.03 |

| Ukunyanzeliswa Hc (A/m) | 2.4 | 25 |

| Ilahleko engundoqo(P400HZ/1.0T)(W/kg) | 2 | 7.5 |

| Ilahleko engundoqo(P1000HZ/1.0T)(W/kg) | 5 | 25 |

| Ilahleko engundoqo(P5000HZ/0.6T)(W/kg) | 20 | >150 |

| Ilahleko engundoqo(P10000HZ/0.3T)(W/kg) | 20 | >100 |

| Obona buninzi bukwazi ukungena kumagnethi (μm) | 45X104 | 4X104 |

| Ukuxhathisa (mW-cm) | 130 | 47 |

| Ubushushu beCurie(℃) | 400 | 740 |