Iribhoni Engaguquki Esekelwe ku-Fe 1K101

Incazelo

| Igama Lomkhiqizo | Iribhoni Engaguquki Esekelwe ku-Fe 1K101 |

| I-P/N | I-MLAR-2131 |

| Ububanzith | 5-80mm |

| Thiukuqina | 25-35μm |

| Ukufakwa kwe-magnetic okugcwala | 1.56 Bs (T) |

| Ukuphoqelela | 2.4 Hc (A/m) |

| Ukumelana | 1.30 (μΩ·m) |

| I-coefficient ye-Magnetostriction | 27 λs (ppm) |

| Izinga lokushisa le-Curie | 410 Tc (℃) |

| Izinga lokushisa le-crystallization | 535 Tx (℃) |

| Ubuningi | 7.18 ρ (g/cm3) |

| Ubulukhuni | 960 Hv (kg/mm2) |

| I-coefficient yokwandisa ukushisa | 7.6 (ppm/℃) |

Isicelo

● Umgogodla we-transformer yamandla aphakathi, umgogodla we-transformer yokusabalalisa

● Ama-cores anganqunywanga e-Toroidal ama-inductor okukhipha acwengekile abushelelezi kanye nama-inductor okufaka imodi ehlukile okushintsha izinsiza zamandla

● Ukunciphisa umsindo kuma-stereo ezimoto, ama-core angakanqunywa e-toroidal okucindezela uhlelo lokuzulazula kwemoto

● Ama-core asikiwe ngendandatho okulungisa amandla e-PFC kuma-air conditioner nama-TV e-plasma

● Ama-cores aqoshiwe angunxande avame kakhulu ama-inductor okukhipha kanye nama-transformer okushintsha izinsiza zamandla, izinsiza zamandla ezingaphazamiseki, njll.

● Ama-core e-Toroidal, angakanqunywa ama-IGBT, ama-MOSFET nama-GTO ama-pulse transformers

● Ama-motor esivinini esiguquguqukayo esinamandla aphezulu, ama-stator nama-rotor ama-generator

Izici

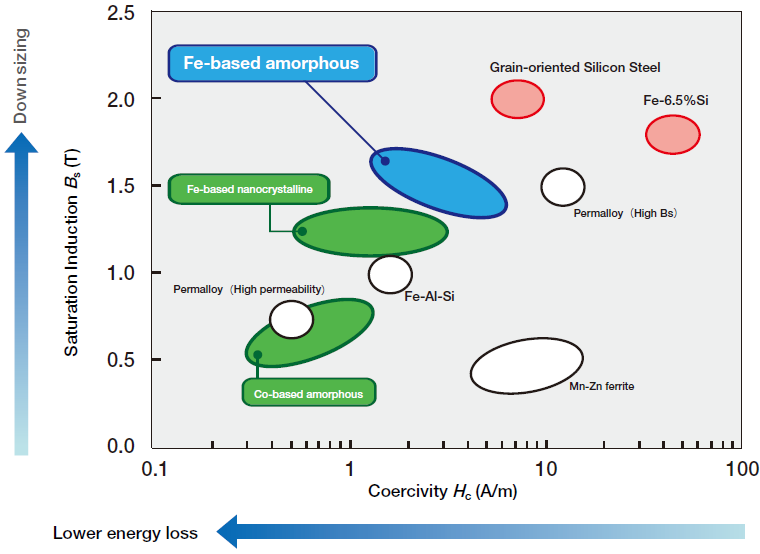

● Ukufakwa okuphezulu kakhulu kwe-magnetic phakathi kwama-alloys amorphous-ukunciphisa usayizi wezingxenye

● Ukuphoqelela okuphansi - Thuthukisa ukusebenza kahle kwezingxenye

● Izinga lokugeleza kwe-magnetic eliguquguqukayo – Ngezinqubo ezahlukene zokwelapha ukushisa okuyinhloko ukuze kuhlangatshezwane nezidingo zezinhlelo zokusebenza ezahlukene

● Ukuqina okuhle kwezinga lokushisa- Ingasebenza ku--55°C -130°C isikhathi eside

● Ama-core asetshenziswa kuma-transformer asebenzisa amandla kahle ngo-75% kune-S9 silicon steel cores uma kuqhathaniswa nokulahlekelwa umthwalo kanye ne-25% yamandla engeziwe °C uma kuqhathaniswa nokulahlekelwa umthwalo.

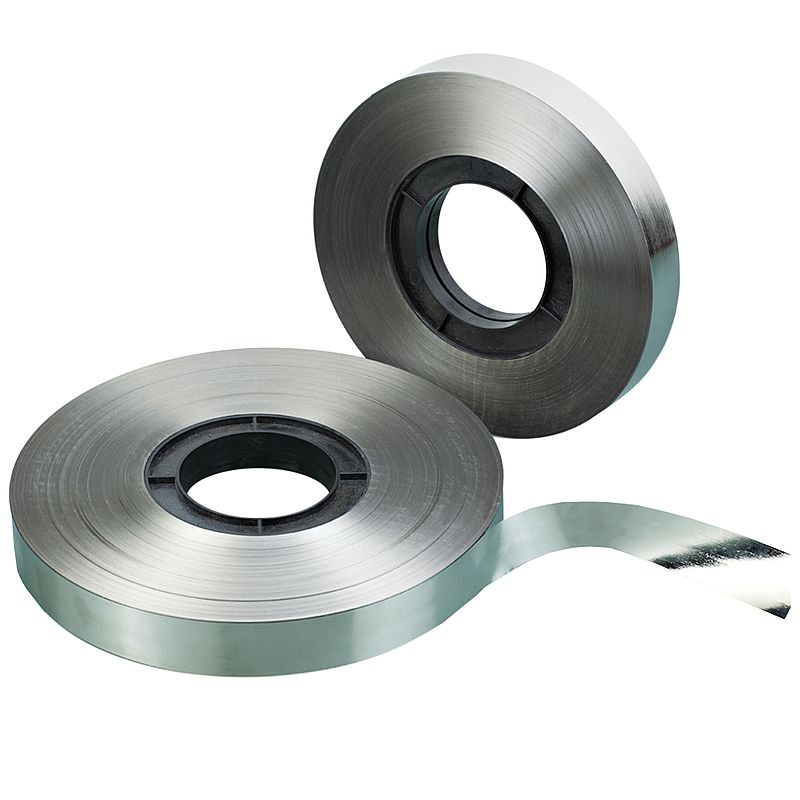

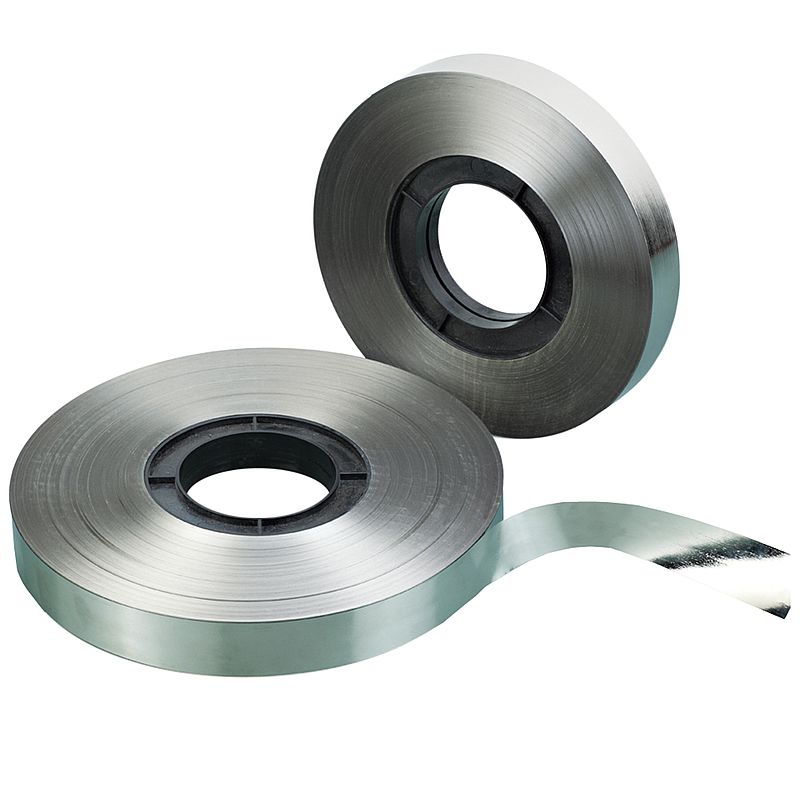

● Inqubo yokukhiqiza imicu emifushane kanye nezindleko zokukhiqiza eziphansi (bheka uMfanekiso 1.1)

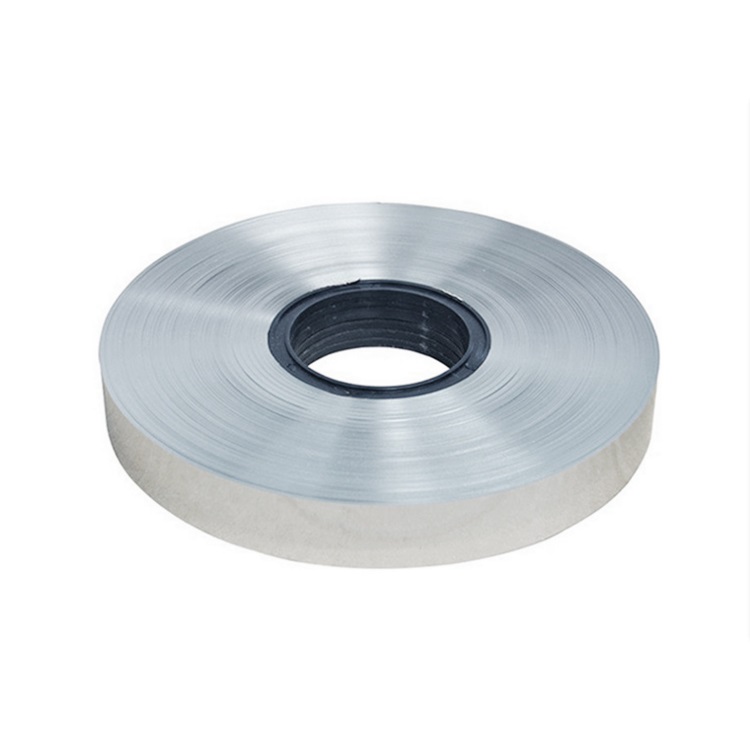

● I-strip inesakhiwo esincane esikhethekile esinquma izakhiwo zayo ezinhle kakhulu zamagnetic (Umfanekiso 1.2) kanye nokuqina kokusebenza.

● Amapharamitha okwakheka kanye nenqubo yomugqa angalungiswa ngokushesha ukuze ahlangabezane nezidingo ezahlukene zokusetshenziswa.

● Kwabaguquli be-inverter abaxhunywe kugridi yelanga yamandla amasha

Umfanekiso 1.1 Inqubo yokukhiqiza iribhoni engenasimo

Umfanekiso 1.2 Bs uma kuqhathaniswa ne-Hc yezinto ezithambile ezihlukene ezisebenzisa amandla kazibuthe

Ukuqhathaniswa kwezinto ezibonakalayo

| Ukuqhathaniswa Kokusebenza Kwe-Fe-based alloys amorphous nensimbi ye-silicon egoqwe ngokubandayo | ||

| Amapharamitha ayisisekelo | Ama-alloy angenawo ukwakheka asekelwe ku-Fe | Insimbi ye-silicon egoqwe ngokubandayo (0.2mm) |

| Ukufakwa kwe-magnetic okugcwala kwe-Bs (T) | 1.56 | 2.03 |

| Ukuphoqelelwa kwe-Hc (A/m) | 2.4 | 25 |

| Ukulahlekelwa okuyinhloko(P400HZ/1.0T)(W/kg) | 2 | 7.5 |

| Ukulahlekelwa okuyinhloko(P1000HZ/1.0T)(W/kg) | 5 | 25 |

| Ukulahlekelwa okuyinhloko(P5000HZ/0.6T)(W/kg) | 20 | >150 |

| Ukulahlekelwa okuyinhloko(P10000HZ/0.3T)(W/kg) | 20 | >100 |

| Ubuningi bokuvuleka kwamandla kazibuthe (μ)m) | 45X104 | 4X104 |

| Ukumelana (mW-cm) | 130 | 47 |

| Izinga lokushisa le-Curie(℃) | 400 | 740 |